What is microfluidics?

Microfluidics relates to the design and study of devices that move or analyze the tiny amount of liquid, smaller than a droplet. Microfluidic devices have microchannels ranging from submicron to few millimeters. To compare, a human hair is about 100 microns thick. Microfluidics has been increasingly used in the biological sciences because precise and controlled experiments can be conducted at a lower cost and faster pace. Lab on a Chip devices use microfluidics for applications such as Point of Care testing of diseases, or Organ on a Chip studies.

How do microfluidics work?

Microfluidics systems work by using a pump and a chip. Different types of pumps precisely move liquid inside the chip with a rate of 1 μL/minute to 10,000 μL/minute. For comparison, a small water drop is ~10 microliter (μL). Inside the chip, there are microfluidic channels that allow the processing of the liquid such as mixing, chemical or physical reactions. The liquid may carry tiny particles such as cells or nanoparticles. The microfluidic device enables the processing of these particles, for example, trapping and collection of cancer cells from normal cells in the blood.

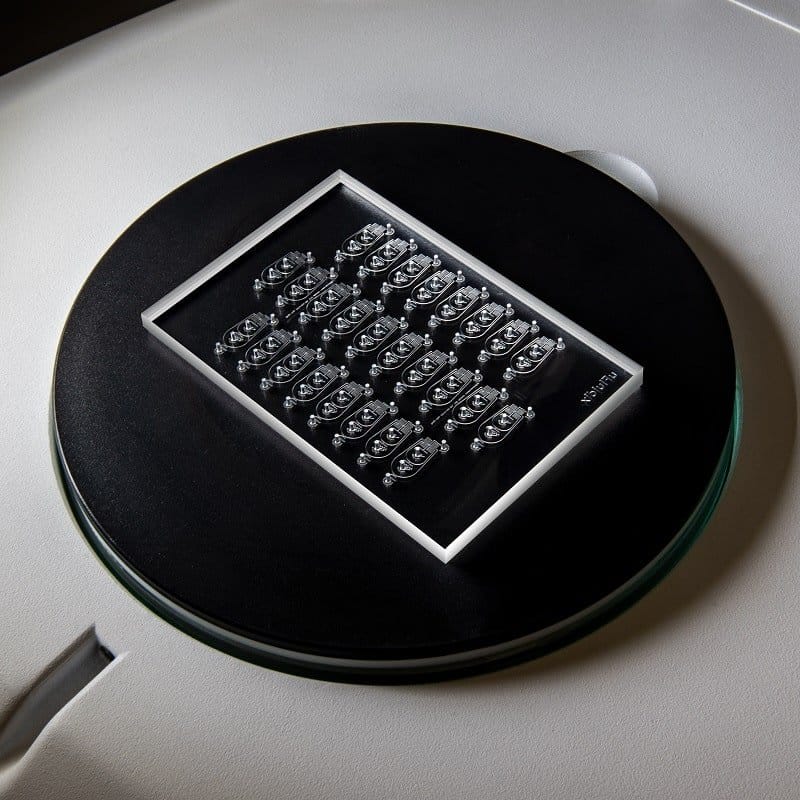

What is a microfluidic chip?

A microfluidic chip is a device that enables a tiny amount of liquid to be processed or visualized. The chip is usually transparent and its length or width are from 1 cm (0.5″) to 10 cm (4″). The chip thickness ranges from about 0.5 mm (1/64″) to 5 mm (1/4″). Microfluidic chips have internal hair-thin microchannels that are connected to outside by means of holes on the chip called inlet/outlet ports. Microfluidic chips are made from thermoplastics such as acrylic, glass, silicon, or a transparent silicone rubber called PDMS.