Microfluidic drug delivery systems

Drug delivery systems aim at the controlled release and targeted delivery of pharmaceutical compounds to the body. These engineered technologies increase the effectiveness of drugs by targeting the infected organ. Besides, they reduce the side-effect by leaving the other organs intact. Microfluidics has shown excellent promise at precise delivering and manipulating liquids. Thus, it has gained tremendous attention in manufacturing more effective drug delivery systems. Conventional drug delivery systems are prone to degrading drugs due to the long intake pathway. Microfluidics is capable of reducing the intake path to reduce the chance of degrading sensitive and unstable drugs.

Conventional methods are incapable of long-term transferring of the drugs. Also, the short half-life of the drugs demands the continuous or on-demand release of the compounds. The drug’s efficiency depends on the accumulation of the compounds near the desired tissue. Typical methods such as oral consumption and injection are inefficient in focusing the drugs around a designated area. Microfluidic technology enables very accurate administration of the liquid. It can be hooked up to an actuator system for on-demand or sustained release of the drugs.

In general, microfluidics has been revolutionizing the fabrication of drug carriers as well as developing direct drug administration chips. Producing drug carriers capable of generating a reproducible release profile as well as controlled release of several compounds with different release profiles necessitates employing an advanced technology for producing drug carriers such as microfluidic technology. Additionally, due to the potential of microfluidic devices for handling minute sample volumes and precise flow control, microfluidic systems for direct drug delivery have entered areas where it had been difficult to achieve high precision drug delivery. Examples include skin, eye, and the brain.

Versatile and precise production of drug carriers with microfluidics approaches

An ideal drug carrier should be able to provide a versatile range of carriers capable of dealing with different environments in different organs. Also, the possibility of adjusting the release rate as well as reducing drug toxicity can be essential for proper drug delivery. Microfluidics offers various approaches for producing drug carriers.

– Self-assembly: Self-assembly techniques are often used to fabricate Nano to micron size drug carriers. Compared to the other two methods, self-assembly normally generates smaller drug carriers. Here, the interface of different fluids is compromised to generate the carriers.

– Spherical microcarriers: Droplet microfluidics is a powerful tool for generating monodisperse microparticles, microbubbles, and microgels. These microcarriers can be generated at kHz frequency to encapsulate the desired compound. The properties of the droplets could be adjusted to fit the specific requirements of the drug such as pH or thermoresponsivity.

– Non-spherical microparticles: It has been shown that the shape of the drug carrier can affect its fate in the body. Therefore, microfluidic techniques for generating non-spherical drug carriers have gained attention.

More details about microfluidics fabrication of spherical and non-spherical microparticles can be found here.

Transdermal drug delivery using microfluidic technology

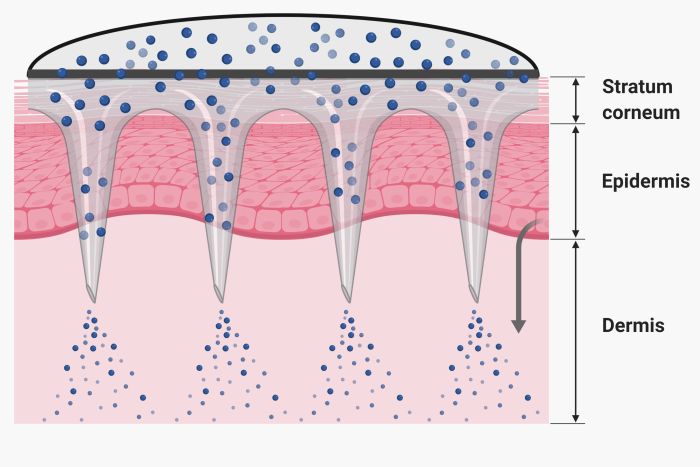

Skin is one of the most common methods for drug administration. Microfluidic chips for skin drug administration normally employ microneedles. Recent advances in fabrication of Microfluidic devices has enabled Microneedles of different types and shapes to be used in microfluidic chips. The examples range from hollow microneedles to solid, porous, dissolvable and coated microneedles. The needles are designed such that they will penetrate through the skin barrier without messing up the nerve fibers. The hollow microneedles can be designed to deliver the desired amount of liquids at optimized time intervals to ensure effective drug delivery. Depending on the designated area and the required volume either a single hollow needle or an array of needles can be used. The solid microneedles are similar to normal sharp needles used in health clinics. They can puncture the skin and be removed to make pores to allow the drugs to enter the body via rubbing a gel, lotion, or a cream. Porous microneedles are similar to solid microneedles with the difference that the pores are pre-filed with a drug. Upon piercing the skin, the pores allow the drug to diffuse into the body. As the name implies, the coated microneedles are coated with the drug. Upon contacting the skin, the drug dissolves in the body. Next, the microneedle can be discarded. The dissolvable microneedles are made of biodegradable materials and will dissolve in the body after a certain amount of time.

Microneedles for transdermal drug delivery

Microneedles often include an array of micron-sized needles for transdermal drug delivery. They were initially made with metals and silicon several drawbacks such as difficulty in loading the drugs and the possibility of breaking up the skin gave rise to the advent of polymeric microneedles. There are three types of polymeric microneedles: dissolvable, degradable, and swellable microneedles.

Microneedles often include an array of micron-sized needles for transdermal drug delivery. They were initially made with metals and silicon several drawbacks such as difficulty in loading the drugs and the possibility of breaking up the skin gave rise to the advent of polymeric microneedles. There are three types of polymeric microneedles: dissolvable, degradable, and swellable microneedles.

Dissolvable microneedles

Dissolvable microneedles are normally used for drug delivery applications. They are water-soluble polymers that can rapidly dissolve in the body after insertion leading to instant drug delivery to the tissue. The dissolving of the polymeric microneedle releases the preloaded drug cargo. The dissolvable microneedles are normally made with polysaccharides such as dextran, sodium alginate, amylopectin. However, other materials such as gelatin, and PVP have also been used.

Degradable microneedles

Degradable microneedles are different from dissolvable microneedles in that they take much longer to degrade after insertion. They often are turned into non-toxic materials that can be discarded in the body. This ability makes them a better choice for long-term drug delivery applications. The drug discharge rate can be controlled via the degradation rate of the polymer. Some polymers that have been used as degradable microneedles are PLGA, Polycarbonate, PCL, chitosan, and silk.

Swellable microneedles

These microneedles neither dissolve nor degrade in the body and operate based on a different mechanism for releasing the drug cargo. Swellable polymer microneedles absorb the interstitial water upon insertion in the body and swell. Swelling and filling with water cause the preloaded cargo to exit and get released in the body. Therefore, as opposed to the other two types, no polymeric residue remains in the body in this method.

Microfluidics ocular drug delivery systems

The eye is a very sensitive organ and eye diseases demand very precise amounts of drugs. Overdoses of the drug can affect the eye negatively and underdoses would not be an effective treatment. Manual methods for eye drug delivery are not reliable. The typical eye drops are not efficient in that the drop might not be the proper size or might fall off the eye. Thus, the eye does not receive the proper amount of drug needed. Very tiny microfluidics microchips hooked up with contact lenses and accompanied with actuators have been designed and developed for drug delivery. Also, rather than being single-use, these microchips are capable of being used multiple times by filling the reservoir with the preferred compound. The reservoir can be filled with a different drug to allow multi-treatments.

Microfluidic drug delivery to the brain

Microfluidic technology carries a promise for more effective neurological probes to cure brain damage and neurodegenerative diseases. Brain intervention requires minimally invasive devices to prevent damaging brain tissues. Also, the devices need to be capable of integration with various modalities. While these requirements cannot be met with traditional metal cannulas, they provide an excellent opportunity for microfluidic technology to shine. These microprobes have been made out of hard materials such as silicon and glass, and soft materials such as PDMS and parylene. These microfluidics devices are capable of integrating electrical stimulation circuits and wireless remote controllers.

Further Reading

- Microfluidic-assisted fabrication of carriers for controlled drug delivery

- Microfluidic Devices for Drug Delivery Systems and Drug Screening

- Design, fabrication and characterization of drug delivery systems based on lab on a chip technology

- Microfluidic system development for drug delivery

- Recent advances of controlled drug delivery using microfluidic platforms

- Microfluidics for advanced drug delivery systems

- Recent advances in the design of polymeric microneedles for transdermal drug delivery and biosensing