Microfluidic Chips: definition, functions, applications

What is a microfluidic chip?

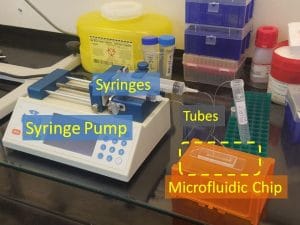

A microfluidic chip refers to an apparatus used in Microfluidics applications. The microfluidic chip  roughly looks like a microscope slide, but with micron-thin internal channels. The micro channels are usually connected to an external pump to drive nano-liters of fluid into the microchannels by means of micro-bore tubes. The micro channels could be as simple as a straight line, or as complex as a network of features (chambers, channels) separated by thin walls, membranes or valves. The diameter of microfluidic channels ranges from 1um to 1000um. The size of the microfluidic chip could be anywhere from ½” to 4” (~1cm -10cm).

roughly looks like a microscope slide, but with micron-thin internal channels. The micro channels are usually connected to an external pump to drive nano-liters of fluid into the microchannels by means of micro-bore tubes. The micro channels could be as simple as a straight line, or as complex as a network of features (chambers, channels) separated by thin walls, membranes or valves. The diameter of microfluidic channels ranges from 1um to 1000um. The size of the microfluidic chip could be anywhere from ½” to 4” (~1cm -10cm).

What materials are used to fabricate microfluidic chips?

Most popular material choice for microfluidic chips is Polydimethylsiloxane aka PDMS. The channels are often cast on the surface of a PDMS sheet and sealed by glass or a slab of PDMS. Microfluidic chips are also made of only glass where channels are etched on the surface of the glass and bonded to another sheet of glass. Silicon is also used where electrical or thermal conductivity is needed. Another material choice for a microfluidic chip are thermoplastics such as Polymethylmethacrylate (PMMA) aka acrylic or Plexiglas, polycarbonate (PC) aka Lexan. Plexiglass and Lexan are both brand names, but often due to popularity are used for PMMA and PC. Another material choice is cyclic olefins such as COC or COP. To fabricate microfluidic chips from thermoplastics, channels are injection molded, rolled or hot embossed on the surface of a flat piece, and then bonded to another piece. Pretty much all materials used to manufacture microfluidic chips, except Silicon, are transparent due to the need to observe what happens inside of the channels. Each material has advantages and disadvantages over others.

How to use microfluidic chips?

Microfluidic chips are often used as part of a larger system. There are three main categories.

1. Chip-in-a-lab setups

This is the most popular way of using a microfluidic chip. The microfluidic chip  is usually connected to a syringe pump using tubes. Fluid is driven into the chip and a physical, chemical, or biological experiment is set. There are thousands of ways this setup could be used. It could be used to separate some particles from other particles, e.g. cancer cells from regular cells. It could be used for synthesis of new materials. It could be used to culture cells in the channel. It may be used for generating water droplets in oil and filling the droplets with genetic materials. The applications of microfluidics are enormous. In this setup sometimes the microfluidic chip is placed in a regular or inverted microscope to see the action or reactions in the channels. The chip may be placed under laser, magnet or piezoelectric acoustic wave makers. The chip may be placed inside an incubator for an extended period of time for organ on chip applications. Microfluidic chips could be used in pretty much any lab that uses liquid of some sort for research.

is usually connected to a syringe pump using tubes. Fluid is driven into the chip and a physical, chemical, or biological experiment is set. There are thousands of ways this setup could be used. It could be used to separate some particles from other particles, e.g. cancer cells from regular cells. It could be used for synthesis of new materials. It could be used to culture cells in the channel. It may be used for generating water droplets in oil and filling the droplets with genetic materials. The applications of microfluidics are enormous. In this setup sometimes the microfluidic chip is placed in a regular or inverted microscope to see the action or reactions in the channels. The chip may be placed under laser, magnet or piezoelectric acoustic wave makers. The chip may be placed inside an incubator for an extended period of time for organ on chip applications. Microfluidic chips could be used in pretty much any lab that uses liquid of some sort for research.

2. Lab on a chip (LOAC)

A true lab on a chip, (LOC) or (LOAC), is when the whole action happens in or around the microfluidic chip. This has also been called a Micro Total Analysis System, uTAS. Such a system should drive the flow through capillary action, or inline pumps. Then control and process the flow, and give results. Although many microfluidics chips have been called LOC, but true LOCs have not emerged yet. The closest could be lateral flow type platforms, such as pregnancy or recently antigen tests, but it remains debatable if lateral flow platforms should be considered microfluidics.

3. Integrated Microfluidic Chip

This category is a middle ground between the above two. The microfluidic chip is usually integrated in an injection molded cartridge, cassette, or kit. The cartridge is then inserted into an analyzer or reader where most of the actuation, sensing and processing takes place. Examples are finger prick blood glucose meters, or many emerging point of care (POC) tests.

Where to buy custom microfluidic chips?

uFluidix is the industry leader in manufacturing custom microfluidics chips. Clients usually approach uFluidix with a concept, or drawing. uFluidix’s engineers give feedback about the chip manufacturability. Once both sides agree on the specification, uFluidix issues a quote and the client places an order to purchase. uFluidix uses the highest industry standards in terms of chips cleanness and quality, as well as using the best practices to protect clients’ IP.

Future of Microfluidics

Microfluidics has been one of the most over-promised or under-delivered technologies in history. There are about one Million articles published in this field with just a handful of commercial applications. However, during recent years microfluidics has been the enabling technology in many emerging applications such as gene sequencing, or point of care testing. The COVID-19 pandemic proved the importance of microfluidics in saving human lives, either through quick identification of the coronavirus mutations, or point-of-care testing, or using flow cytometry for vaccine research, or organ on a chip for understanding of the vial entry, or cells response, and many others.