Organ-on-a-Chip: Microfluidic technology that can revolutionize the pharmaceutical industry

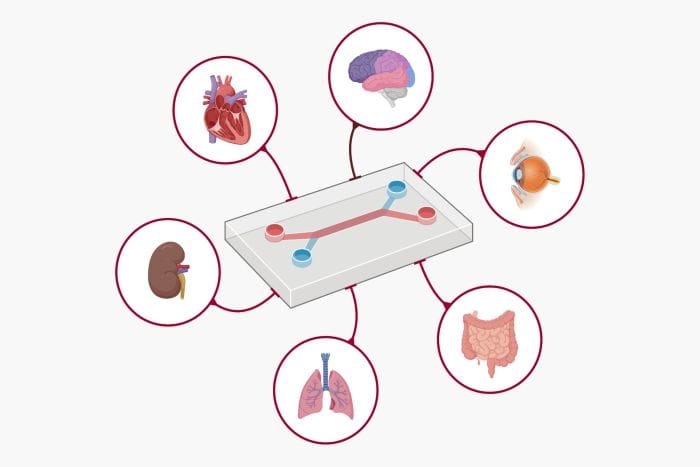

Organ-on-a-Chip devices or tissue chips are among the microfluidic chips with the highest demand on the market that have been able to revolutionize the pharmaceutical industry. In recent years, a wide variety of Organ-on-a-Chips have been designed and successfully tested — heart on a chip, liver on a chip, brain on a chip, kidney on a chip, intestine on a chip, and eyes on a chip, to name but a few.

What is Organ-on-a-Chip?

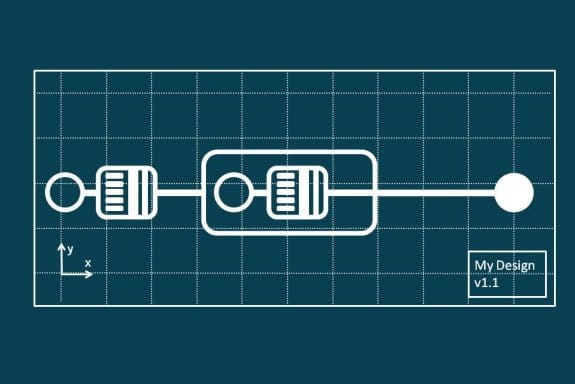

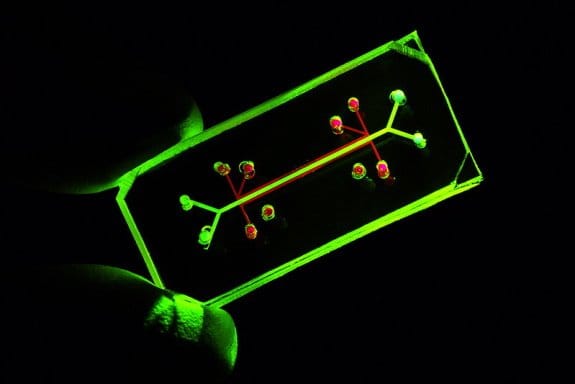

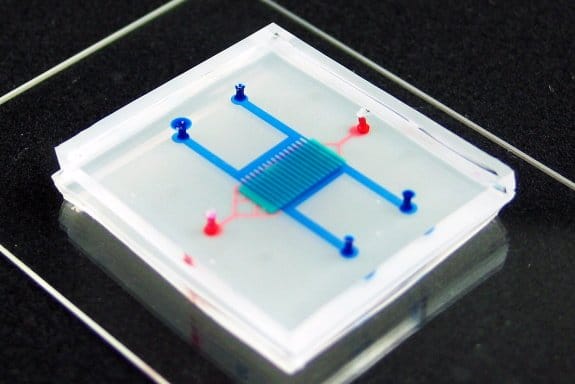

Organ-on-a-chips are tiny devices, usually smaller than the palm of a hand, that employ microfluidics technology to create microchannels and chambers at the micron-scale size for cell culturing in a microenvironment similar to that of the cell’s natural habitat. These microfluidic devices are sealed and sterile and made of an optically transparent material that allows visual and real-time monitoring and analysis of the cells. The Organ-on-a-Chip devices are made of a biocompatible polymer material and are of a modular nature. The modularity of the chips allows multiple modules such as sensors and actuators to be connected to the main microfluidics chip for analysis or manipulation of the cells. Organ-on-a-Chip has advantages over conventional cell culture methods such as Petrie dishes and flasks or 3D cell culturing techniques and can shift the paradigm in pharmaceutical and biotech industries.

Why is Organ-on-a-Chip important?

Complying with the safety protocols and procedures for rolling out a new line of medicine is arduous. It requires multiple steps of preclinical and clinical tests to validate the applicability of a new medicine. The drug development pipeline can go off the rails at each of the four stages (Discover, Preclinical research, Clinical trials, FDA review) leaving the pharmaceutical companies with a significant financial loss. The further down the road the new compound fails, the higher the costs of the failure. The estimated cost associated with developing a new compound that gains market approval is around $2.5 billion dollars. New technologies can be of great help to assess the functionality of the new medicine before taking it to the clinical trials to reduce the costs. 2D testing and in-vitro analysis of pharmacodynamics and pharmacokinetics are common practices before taking the drug to the next steps including preclinical testing. The organs in our body are of a 3D nature and the complex behaviour of cells cannot be adequately modelled in 2D cultures such as 96-well plates. Animal models are also not ideal for testing human-specific medicines. The technology needs to upgrade to enable taking advantage of complex microenvironments at high-throughput. Among the novel technologies microfluidic tissue chips, commonly known as Organ-on-a-Chips (OOC), have shown to be very successful in this regard.

Complying with the safety protocols and procedures for rolling out a new line of medicine is arduous. It requires multiple steps of preclinical and clinical tests to validate the applicability of a new medicine. The drug development pipeline can go off the rails at each of the four stages (Discover, Preclinical research, Clinical trials, FDA review) leaving the pharmaceutical companies with a significant financial loss. The further down the road the new compound fails, the higher the costs of the failure. The estimated cost associated with developing a new compound that gains market approval is around $2.5 billion dollars. New technologies can be of great help to assess the functionality of the new medicine before taking it to the clinical trials to reduce the costs. 2D testing and in-vitro analysis of pharmacodynamics and pharmacokinetics are common practices before taking the drug to the next steps including preclinical testing. The organs in our body are of a 3D nature and the complex behaviour of cells cannot be adequately modelled in 2D cultures such as 96-well plates. Animal models are also not ideal for testing human-specific medicines. The technology needs to upgrade to enable taking advantage of complex microenvironments at high-throughput. Among the novel technologies microfluidic tissue chips, commonly known as Organ-on-a-Chips (OOC), have shown to be very successful in this regard.

Organ-on-a-Chips are microfluidics systems that are designed to create a more complex physiological environment to culture and control the cells in a 2D or 3D structure of a specific organ in the body. These microfluidics chips allow precise control over the microenvironment to mimic the cell’s natural physiological conditions. In recent years, Organ-on-a-Chip has caught tremendous attention for drug development and disease modelling. Microfluidic technology has empowered researchers and the pharmaceutical industry to test the drugs in preclinical settings in a much more realistic manner compared to conventional 2D cell cultures and animal models. The transparent material used in manufacturing Organ-on-a-Chip enables real-time imaging and monitoring of the cells. Also, fluid flow in microfluidic channels in the vicinity of the cells allows nutrients, medicine, cytokines, etc. to be delivered to the cells besides exposing them to the natural shear forces and flow dynamics of the body.

How does Organ-on-a-Chip work?

In principle, an organ-on-a-chip consists of a main microfluidics chamber lined with human cell lines connected to a network of microchannels for perfusion and waste withdrawal. The microfluidics chamber is made of a biocompatible material. Normally, polydimethylsiloxane (PDMS) is used for creating these microchambers. PDMS is the most-widely used polymer used in the microfluidic industry due to its superior properties such as simple and standard fabrication methods, biocompatibility, optical transparency, nontoxicity, compressibility and permeability to gases. The cells of interest are then cultured in this microchamber in sterile conditions. The microchamber can be a simple chamber with micron-scale dimensions. The cell culture microchamber can be modified in a variety of ways to help to better mimic the cell’s natural environment. A broad range of surface patterning or modification can be exploited according to the specifications of the experiment. For example, modifying the surface with natural ECM-derived proteins can increase the adhesion of the adherent cells to the surface. It has been shown that micro/nanopatterning the surface can help cells’ growth, differentiation, and adhesion as well as boost protein expression levels.

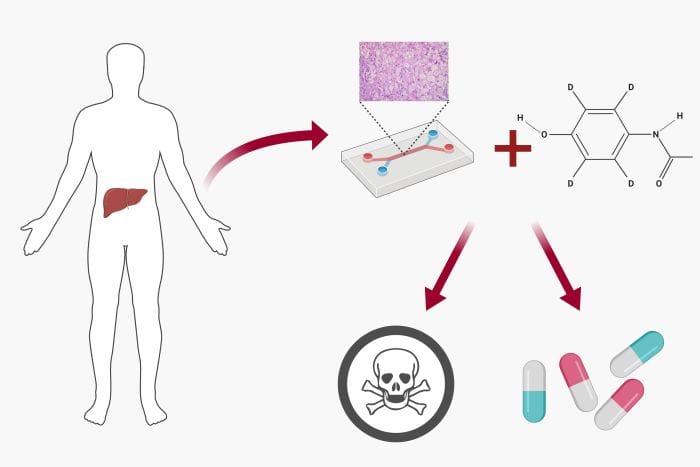

The microchamber is often connected to multiple side microchannel. These side microfluidics channels can serve multiple purposes. They can be used to deliver nutrients, bacteria, viruses, and chemicals to the cells or wash the cells and discard the waste. Moreover, they can be employed to manipulate the cells mechanically or electrically. In more sophisticated systems, the organ-on-a-chip can include multiple layers of cells to make a more comprehensive model or to study cell interaction. Organ-on-a-Chip related to different organs can connect to each other for the simultaneous analysis of multiple organs. For example, a heart on a chip can connect to a liver on a chip through their common vascular channels for cardiotoxicity testing of a new drug. The combination of the cell culturing microchambers and the assisting microfluidic side channels create near-human environments that are biologically relevant for cell growth, toxicity testing, and personalized medicine.

Where can I buy Organ-on-a-Chip?

As Organ-on-a-Chips developed and showed promise in the pharmaceutical industry as well as academic and fundamental research, the demand for these chips in the market increased. The microfluidic chips normally require clean-room infrastructure for fabrication that can be quite costly. Although you can buy an off-the-shelf product, in many cases the Organ-on-a-Chip requires to be tailored according to the specifications of your own experiment. uFluidix has accrued many years of experience in the design and Microfluidics fabrication of single-layer and multi-layer microfluidics Organ-on-a-Chips. Whether you have your design ready and you want your Organ-on-a-Chip to be fabricated affordably or you have an amazing idea for an Organ-on-a-Chip but no experience in design and fabrication, uFluidix will be there to help. Contact us today to purchase your Organ-on-a-Chip fabricated with high quality, and at a reasonable price.

Read more on how microfluidics based organ-on-a-chips are used to reduce the drug development failure rate and for personalized medicine.

Explore the different aspects of designing an organ-on-a-chip. Learn about the cell source, flow dynamics, and the structure of the organ-on-a-chips.

There are questions that should be addressed before moving the organ-on-a-chips to mainstream applications. Learn more about these aspects of organ-on-a-chips.

Discover the advancements of the microfluidics approaches for recapitulating the brain function on brain-on-chip devices.

Heart-on-chip devices employ microfluidic technology and tissue engineering principles to create functional models of the heart.

In a liver-on-a-chip, a highly controlled microfluidics cell culture environment is employed for drug toxicity screening and metabolism analysis.