For over three decades, a revolutionary impact of microfluidic technology on science and industrial applications has been envisioned; however, such predictions have not been met regardless of a large number of academic publications and even patents. Fervently, the number of publications rose from a few dozen publications per year in 2000 to the thousands in 2012; yet a killer application has not been realized either for academic research nor for the industry1. The obvious question is why the gap between the proof-of-concept microfluidic development found in these publications and the mainstream market has not yet been breached.

From the economic perspective, the adoption of new technologies must be easily adaptable and cost-effective, unfortunately, these two requirements have not been properly met. Most publications regarding microfluidics are found mostly in engineering journals1 or in patent form2, thus limiting an immediate adoption due to their complexity. However, it’s not to say that microfluidics adoption is not on its way as applications range from chemical synthesis of organics, inorganics polymer particle as well as in emulsions, microencapsulation, steam reforming3 and biochemistry in high-throughput formats2. Additionally, part of the easy adoption of microfluidics by industry is to address the technical problem of the complexity of scalability in which complex flow distribution and intricate reaction detection methods are required3,4. This latter issue mostly affects large-scale applications of microfluidic reaction technology.

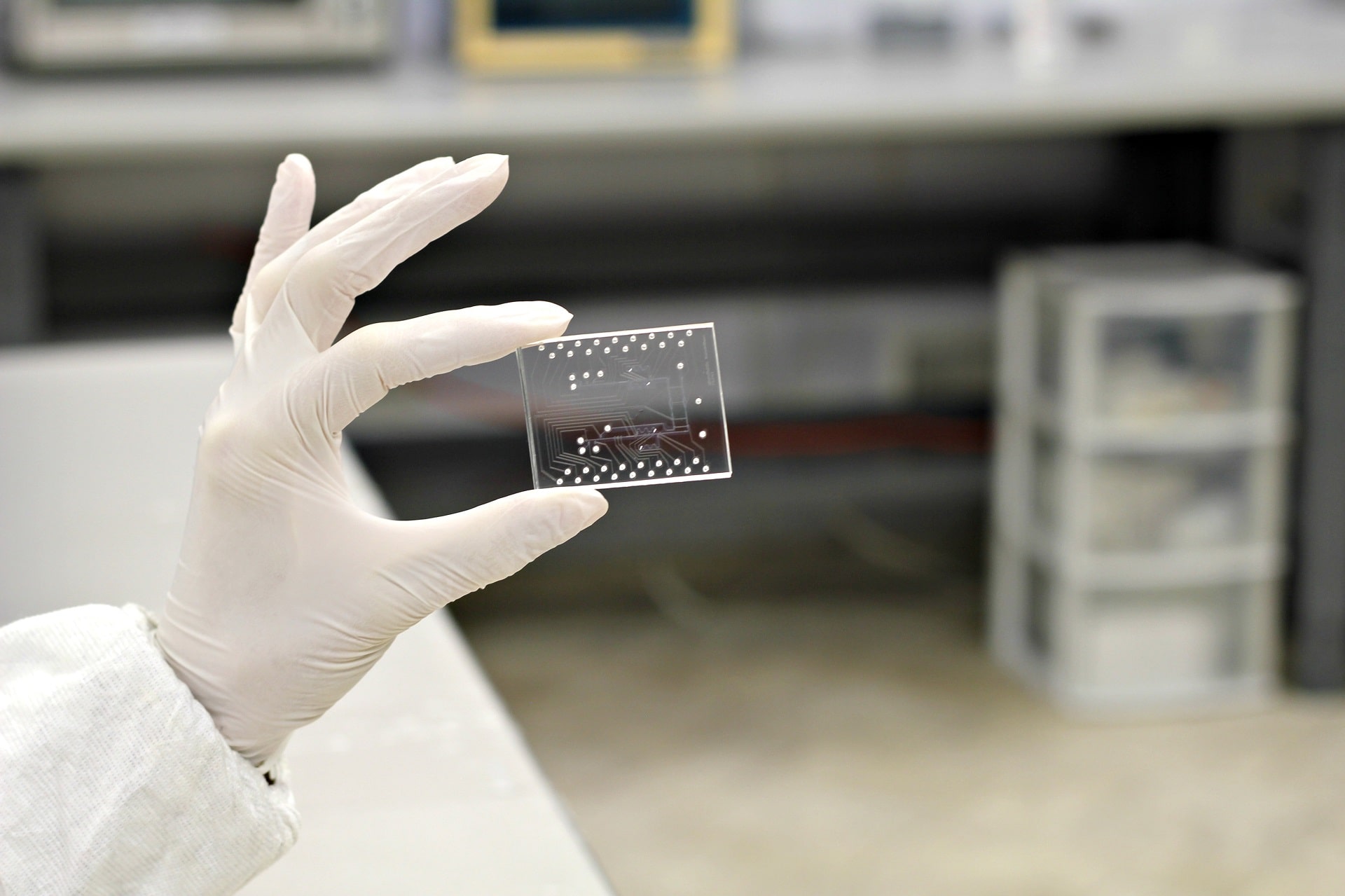

As mentioned before, microfluidic technology must be cost-effective to be feasible, and this must be straightforwardly met when costly and delicate reagents are involved. The obvious advantages provided by microfluidics of small-volumes and precise liquid handling2 can provide cost-effective high throughput biochemical assays and diagnostics3. However, to widely implement these technologies, portability, miniaturized and stand-alone lab-on-a-chip devices are still needed2. Nevertheless, this remains a largely an unfulfilled vision of the microfluidics community.

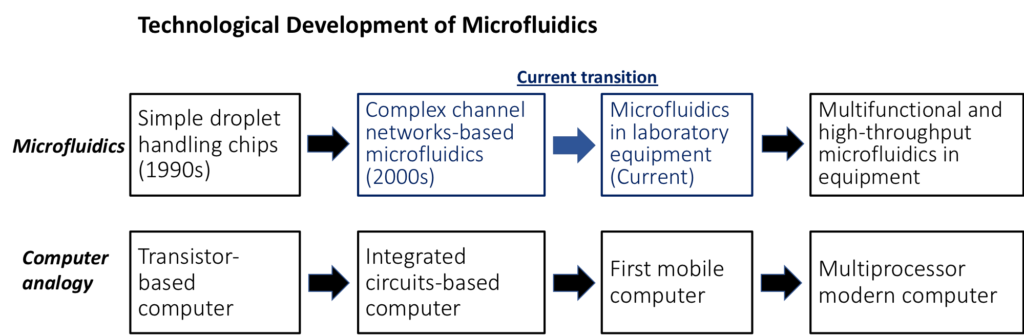

Fig. 1. An analogy of the technological development to the modern computer. The blue colour indicates the current transition in technology progress.

To understand the current technological state of microfluidics, I can make an analogy to the history of the digital computer. In my opinion, we are seeing a transition in the technological development of microfluidics where advanced microfluidic chips are now being incorporated into laboratory equipment (Fig. 1). And as mentioned before, such applications are finding their niche in biochemical assays and diagnostics. Once, such device integration is widely adopted, we can expect a fast improvement of multifunctional and high-throughput microfluidics platforms.

Indeed, microfluidics has a large potential to be integrated into powerful platforms. However, the exact timeline of microfluidics fully reaching the consumer market is still hard to predict as it will depend on the demand of small volume handling, cost feasibility based on the application and the technical aspects of the scalability.

1. Caicedo, H. H.; Brady, S. T. Microfluidics: The Challenge Is to Bridge the Gap Instead of Looking for a ‘Killer App.’ Trends Biotechnol.2016, 34 (1), 1–3.

2. Chiu, D. T.; deMello, A. J.; Di Carlo, D.; Doyle, P. S.; Hansen, C.; Maceiczyk, R. M.; Wootton, R. C. R. Small but Perfectly Formed? Successes, Challenges, and Opportunities for Microfluidics in the Chemical and Biological Sciences. Chem2017, 2 (2), 201–223.

3. Elvira, K. S.; i Solvas, X. C.; Wootton, R. C. R.; deMello, A. J. The Past, Present and Potential for Microfluidic Reactor Technology in Chemical Synthesis. Nat. Chem.2013, 5 (11), 905–915.

4. Amador, C.; Gavriilidis, A.; Angeli, P. Flow Distribution in Different Microreactor Scale-out Geometries and the Effect of Manufacturing Tolerances and Channel Blockage. Chem. Eng. J.2004, 101 (1–3), 379–390.

Enjoyed this article? Don’t forget to share.

Adrian Zambrano

Adrian Zambrano is a scientist at the Max Planck Institute of Molecular Cell Biology and Genetics in Germany where he synthesizes protein/polymer scaffolds for micro-droplets and utilizes microfluidics for the encapsulation of enzymatic DNA replicators and other DNA-based assays. He holds a Ph.D. in physics from the University of Paris-Saclay/CNRS and B.Sc. in chemical engineering from the University of Nevada, Reno. His personal interests lie in the commercialization and development of high-throughput assays based on microfluidic technology.