Over the last two years, I have seen an increased interest in using simulation software to better understand microfluidics processes. The two most common and important reasons for considering integration of simulation software into microfluidics processes have been to reduce device cost and improve quality control.

Microfluidics processes are truly multiphysics in nature, requiring a robust simulation tool to accurately capture all of the physics involved. Certain physics like surface tension become more prominent at the micro scales at which microfluidics processes work. Coupled to surface tension are other physics in play, such as electro-osmosis, electro-kinetics and visco-elasticity. In short, microfluidic simulations can be very complex. An accurate simulation tool can provide insights to the designer about the microfluidic device and help him develop a more efficient and better design. One such example is analyzing an acoustophoretic particle focusing device that removes a variety of objects from solutions in a microfluidic channel. The process is applicable to malignant cell removal, nanoparticle separation, and sequestration of suspended liquids. Another application is to understand the dynamics that govern the formation of lenses using fluids (optofluidics) in microfluidic channels. Optofluidics combines elements of optics and microfluidics and finds applications in biosensors, displays, lab-on-chip devices, molecular imaging and lenses.

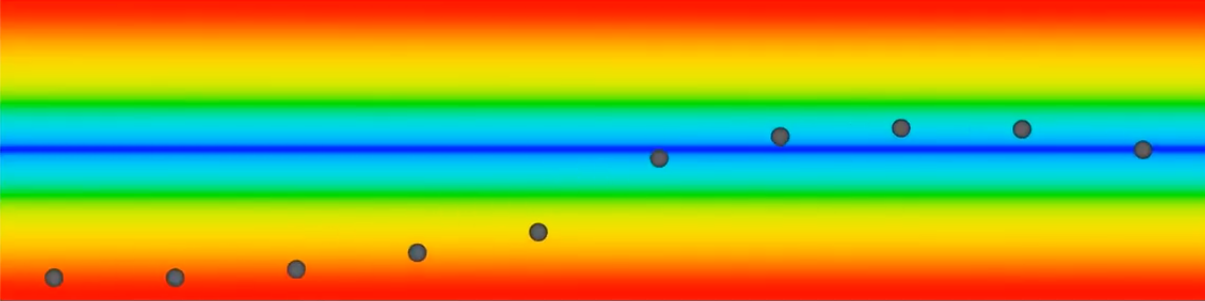

Going back to the acoustophoretic particle focusing device, using inappropriate control parameters such as acoustic wave frequency can lead to forces that may cause some malignant cells to avoid getting separated from the bloodstream. The animation below shows an acoustophoretic device that focuses all the representative malignant particles to the middle of the device, which can then be safely extracted from the solution.

Simulation of an acoustophoretic device where particles enter the computational domain at an off-center location in a microchannel of 500μm height and 2mm length. Under the influence of a standing acoustic wave at a frequency of 1Mhz, the particles are focused in the middle of the channel.

Similarly for the optofluidics device, hydraulic parameters such as flow rates can alter the shape of the lens significantly. Understanding how flow rates affect the shape of a lens ensures the proper illumination of cell bodies in a solution, making it easy to study their behaviour. Also, using simulation the shape of the microfluidics channels can be optimized to produce the desired lens shapes with minimum material, saving on the cost of manufacturing. This animation shows an optofluidic device forming different lens shapes.

Simulation showing lens formations for different flow rate combinations. In this case different lens types are formed, such as bi-convex, plano-convex and meniscus.

The microfluidics industry is currently on the so-called slope of enlightenment of the Gartner Hype Cycle curve for emerging technologies, thanks to the increased research into microfluidics processes and applications. An important aspect of microfluidics processes is the “precise” control and manipulation of fluids that can be attained by thorough experimentation complimented by accurate simulations. Integration of simulation software in your workflow can provide precise control over a microfluidics process while maintaining the economic viability and the reliability of the device.

Enjoyed this article? Don’t forget to share.

Adwaith Gupta

Adwaith Gupta is a Senior Computational Fluid Dynamics Engineer at Flow Science Inc and an independent Artificial Intelligence Engineer. At Flow Science, he is an active member of the product development team; leads the academic programs; oversees the development of state-of-art optimization software; and spearheads the expansion of FLOW-3D (Flow Science’s multiphysics modelling software) into the microfluidics industry. He obtained his MS from Stanford University majoring in Fluid Mechanics with a focus on computational modelling and scientific computing.