Centrifugal microfluidic platforms, also called compact microfluidic biodisks or compact disks (CD), have been around for almost four decades and have seen a surge in technology advancement in the last decade1. CDs are used in rapid immunoassaying and clinical biochemistry for blood diagnostics. They are used as micro total analysis systems (μTAS), in which several individual assays are embedded and run simultaneously on a single chip. They operate on simple inexpensive motors programmed for hands-free control and do not require external actuators such as magnets or surface treatments. Basically, CDs are great, and this article should end here. Unfortunately, there is a catch: due to unidirectional (radial) centrifugal forces, CDs run out of real estate faster than non-rotating microfluidic devices.

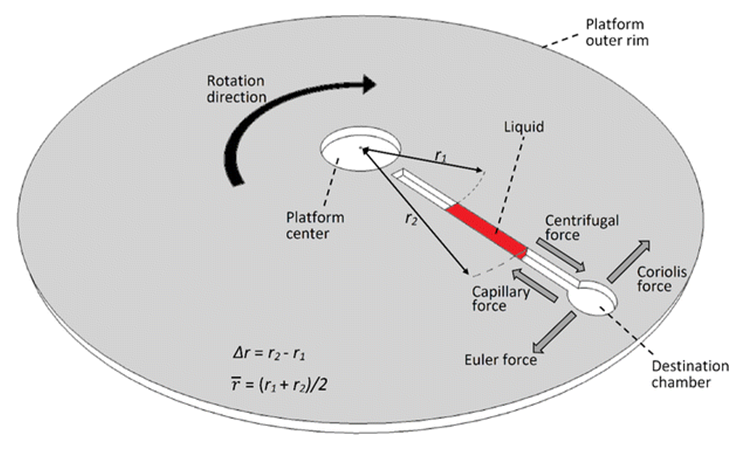

Schematic highlighting various body forces applicable to a radial column of water inside the channel of a CD. Notice the radially outward-acting centrifugal force which is crucial to moving the fluid towards the edge of the disc.

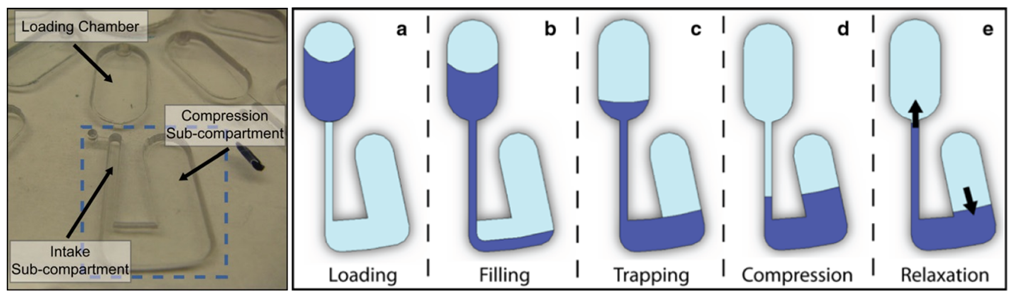

Fluids only move radially outwards, limiting the number of analytical steps a CD can perform. In 2010, Gorkin et al.2 released one of the earlier papers where the authors suggest pneumatic pumping to counter the unidirectionality of CDs.Their idea was to store the centrifugal energy as compression energy and release it when needed to launch the fluid towards the center. Gorkin et al. conducted a series of experiments, to understand the correlation between a certain rotational speed and the corresponding amount of compression energy storage-Higher rotational speeds cause more compression energy storage.

Photo of the CD used by Gorkin et al. and the 5 stages of pneumatic pumping in the CD. Compression of the air in the compression sub-compartment happens because of the disc rotation. The final relaxation stage is attained by slowing the disc rotation.

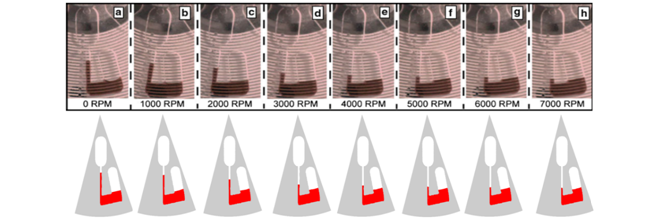

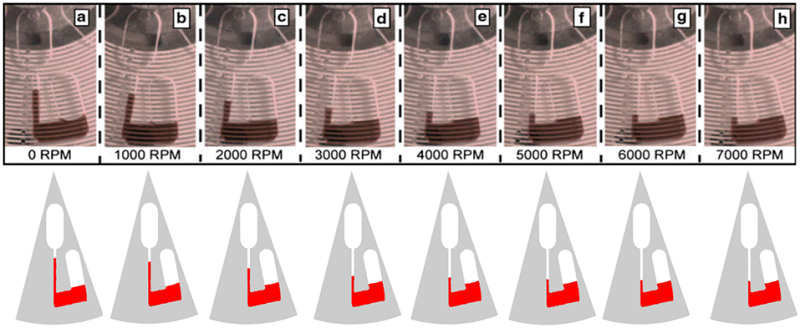

Experiments are at the core of designing microfluidic devices. But conducting enough experiments and maintaining a perfect control environment for each experiment can become prohibitive. Complex designs require complex experimental setups and analysis. Can modeling share some burden of the experiments? The answer to that question is yes, based on the sequence of images below. Quantitatively, an excellent correlation (R2>0.99) exists between the experimental and the FLOW-3D simulation results.

Top row: Images of the section of the CD rotating at different speeds. Bottom row: Simulation counterpart for each rotational speed used in the experiments.

The real-estate management of uni-directional flow devices such as centrifugal microfluidic platforms is difficult but attainable. Innovative ideas such as pneumatic pumping, followed by experiments and supported by accurate simulations, alleviate the major limitation- available real estate – of centrifugal microfluidic platforms while maintaining the benefits of these devices.

1. Bithi, S. S. & Vanapalli, S. A. Microfluidic cell isolation technology for drug testing of single tumor cells and their clusters. Scientific Reports 7, 41707, doi:10.1038/srep41707 (2017).

2. Park, I. S. et al. Real-Time Analysis of Cellular Response to Small-Molecule Drugs within a Microfluidic Dielectrophoresis Device. Anal Chem 87, 5914-5920, doi:10.1021/ac5041549 (2015).

Enjoyed this article? Don’t forget to share.

Adwaith Gupta

Adwaith Gupta is a Senior Computational Fluid Dynamics Engineer at Flow Science Inc and an independent Artificial Intelligence Engineer. At Flow Science, he is an active member of the product development team; leads the academic programs; oversees the development of state-of-art optimization software; and spearheads the expansion of FLOW-3D (Flow Science’s multiphysics modelling software) into the microfluidics industry. He obtained his MS from Stanford University majoring in Fluid Mechanics with a focus on computational modelling and scientific computing.