In the early 1900s when digitization of data came about to be a boom in data processing technology, one wouldn’t have imagined that similarly a droplet containing biological samples could be digitized in order to be processed in a programmed order of complex reactions. Digital microfluidics (DMF) has made it possible to perform a stepwise procedure on precise quantities of liquid on a microscale thereby combining the benefits of microfluidics as well as discrete processing of information.

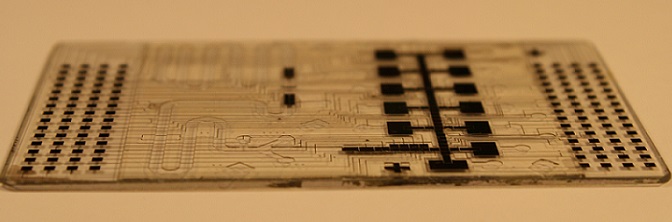

The digitization is achieved by a technology called electro-wetting on dielectric (EWOD). As the name suggests, EWOD involves “electric field” and “wetting of dielectric”, later as a result of the former. The ability to capture liquid droplets on a layer of dielectric using electric field help achieve the DMF control. In DMF, picoliter- to microliter-sized droplets are independently addressed on an open array of electrodes coated with a hydrophobic insulator1. The EWOD device used for DMF mainly consists of multiple layers stacked intelligently to form a simple circuit [Figure 1].

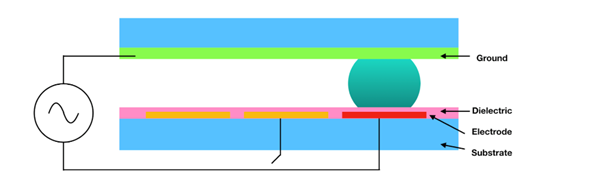

Figure 1. Schematic cross-section of a typical EWOD device showing all layers7.

The figure shows a two plate EWOD device. The bottom plate consists of electrodes and a dielectric layer and the top plate consists of a common grounded electrode. The circuit is broken as long as there is air between these two plates, but the circuit is completed when an electrode under a droplet is supplied with high voltage. This is due to the fact that the ions in the droplet provide a medium for conduction through the droplet. The droplet along with the capacitive dielectric layer and the electrode form the total impedance of the circuit. Once the electrode is supplied with high voltage it causes a decrease in the contact angle of the droplet and thereby making the droplet to stick to the electrode. Further, by switching the supply to the adjacent electrode the droplet can be moved to that electrode, establishing movement on the plate. This movement on droplet can be in order to move, mix two drops, split a bigger drop into two smaller droplets which are the basic functions to carry out a bioassay on the chip (watch a video below).

Two-plate digital microfluidics for dispensing, mixing, and merging droplets. Credit: Wheeler Lab.

As seen in the figure, the bottom most layer is the substrate which can be glass or silicon wafer or a PCB board. Several electrodes are patterned on the substrate. The pattern of the electrodes is designed based on the application of the device. Thin film electrodes and the connecting lines can be made with a conductive material (For example Gold and Chrome are popular choices). The electrodes are then coated with a thin layer of dielectric material. The choice of dielectric material is based on the dielectric constant of the material and the ease of fabrication. Parylene, SU-8, PDMS are common choices for the dielectric layer. The dielectric layer is topped by a layer of hydrophobic material. The hydrophobic layer is important in an EWOD device since the droplets and the biological content of the droplets can stick to the dielectric layer and cause cross contamination as well as damage the dielectric layer over time. A thin layer of silane, Teflon or Cytop is usually used to form the hydrophobic coating. Useful literature has been published on possibilities of different materials to make the EWOD devices2.

The biggest advantage of EWOD is the precise control over individual droplets in the system. Due to this feature EWOD devices can be programmed to carry out biological assays on a chip. Programming the assay is as straightforward as programming the controller that switches on/off the electrodes. Another big advantage of this technology is the ability to interface with other technologies to fabricate more complex devices that can perform a variety of assays and readouts. For example, Shih et al3 combined traditional droplet microfluidic platform with an EWOD chip to step up the number of droplets that can be processed. They used the ability of droplet microfluidics to make many droplets rapidly and then transfer the stream to an EWOD platform to process the micro-reactors individually.

Hu et. al. combined the cutting edge technology of carbon nanotubes with EWOD to exploit the benefits of both technologies4. Some groups have also successfully attempted fabrication of MOSFET biosensors integrated with EWOD platform for easy preparation of samples followed by on-chip detection of reaction signal5.

A shortcoming that DMF devices have faced is the inability to process more than several droplets at a time; micro-fabrication of high-throughput EWOD systems is a field still under R&D. Apart from high-throughput, the other challenge that DMF faces is integration with other types of microfluidic technologies. It would be tremendously successful to integrate different sub-technologies from the wide umbrella of microfluidics to process samples for even more complex operations. Some groups have attempted creating thin film electronics (TFT) chips6 in order to process thousands of droplets at a time which is a promising avenue for the commercialization of DMF systems in the future. The TFT film replaces the electrode layer in a conventional EWOD device in this example. This technique facilitates the high throughput fabrication and actuation of many electrodes on a smaller platform. The success of such projects shows promise that the commercialization of EWOD devices as an affordable point of care tool is possible in the future.

Nevertheless, we are living in exciting times as the EWOD scene in the industry is encouraging. Advanced Liquid Logic (acquired by Illumina Inc. in 2013) used EWOD digital microfluidic devices to provide an automated solution to complex liquid handling processes in laboratories. Their work and talent now thrives and is continued by the genomic sequencing giant Illumina. The company recruited digital microfluidics technology to create NGS preparation platforms. Miroculus, another startup in San Francisco is exploiting the EWOD technology to bring affordable diagnostics to market. Further, GenMarkDx uses electrowetting to perform blood culture identification. Raindance as well is another name in the digital PCR world. Automation EWOD devices is an important aspect and automation engineers aren’t far behind in providing affordable off the shelf solutions for labs and small groups to automate DMF systems. Sci-Bots is a company that makes DMF driving robots and automation tools that are affordable and compact.

With the help of EWOD, material science and cutting edge fabrication techniques microfluidics has come a long way in the light of digital microfluidics and continues to hold potential for further merging of platforms to create more complex and compact lab-on-a-chip devices.

1. Choi et al. (2012) Digital Microfluidics Annu. Rev. Anal. Chem. 2012. 5:413–40

2. Lin et al. (2010) Low Voltage Electrowetting-on-Dielectric Platform using Multi-Layer Insulator, Sensors and Actuators B: Chemical Volume 150, Issue 1, 465-470

3. Shih et al. (2015) A droplet-to-digital (D2D) microfluidic device for single-cell assays, Lab Chip, 2015,15, 225-236

4. Hu et al. (2007) Electrowetting devices with transparent single-walled carbon nanotube electrodes, Applied Physics Letters 90, 093124

5. Choi et al. (2012), Integration of field effect transistor-based biosensors with a digital microfluidic device for a lab-on-a-chip application, Lab Chip, 2012,12, 1533-1539

6. Hadwen et a. (2012) Programmable large area digital microfluidic array with integrated droplet sensing for bioassays, Lab Chip, 2012,12, 3305-3313

7. Raje M. (2018) A Review of Electrowetting on Dielectric Applications of Carbon Nanotubes, Nanomedicine & Nanotechnology Open Access, Volume 3, Issue 4

Enjoyed this article? Don’t forget to share.

Manasi Raje

Manasi Raje is a microfluidics R&D engineer working in Bay Area, California. She is working at Shield Diagnostics and developing diagnostic devices for affordable testing of infectious diseases. She holds training in Biomedical Engineering and Electronics Engineering. Manasi has experience in the design and fabrication of a variety of lab-on-a-chip devices. She developed a number of application specific and high-throughput-attempting microfabrication methods during her time at JBEI that let to a patent. Her microfluidic roots are based in Hui lab at UC Irvine where she developed microfluidic digital logic circuits for on-chip automation of lab processes which let to multiple publications, presentations and a national award. She is involved in multiple conferences and technical committees in field of Microfluidics.