When I started my pursuit to become a Biomedical Engineer, the last thing I would have ever thought I would end up working in is microfluidics. And why is that? Well, as others in the field have previously discussed, along with friends and family, and even myself; we did not know what microfluidics was. However, this shortly changed as I was fortunate to stumble into the Bio-MEMS laboratory of Dr. Marc Madou at the University of California, Irvine. Dr. Madou specializes and focuses on a specific area of microfluidics known as Compact-Disk or CD microfluidics. One of my fondest memories in the lab was watching a video of Dr. Madou on TedxTalks describing how he was going to turn a Sony Discman into a medical diagnostic device and all I could think to myself was…“What is a Discman?”

Your CD player as a medical diagnostics device | Dr. Marc Madou | TEDxUCIrvine

CD microfluidics is somewhat relatable to a centrifuge system where CD microfluidics are based on resulting centrifugal forces as a microfluidic chip spins around a center axis commonly using a motor. Because of this, there is no need for the myriad of pumps and hoses that are generally found in lateral flow microfluidics. Research in CD microfluidics not limited to the small amount of research labs that specialize in pushing forward technological advances that these systems are capable of. Companies such as Siemens, Samsung, or even the ill-fated situation revolving Theranos are clear indications that CD microfluidics makes up a small chunk of the microfluidic market. A recent publication estimates the North America microfluidics market is expected to reach approximately 10.25 billion USD by 2025 at a CAGR of 18.5% with the healthcare sector projected to lead over half of the market share1.

The healthcare sector stands to advance from the implementation of microfluidics in various services such as Point-of-Care (POC) diagnostics, immunoassays, genotyping & sequencing, and microarray analysis to name a few1. If you do a quick search, you can find that an assortment of companies utilizing centrifugal microfluidics focuses on POC diagnostics. CD microfluidics allows the associated devices and systems to be portable, low cost, and easy to use; making it an ideal for applications in POC diagnostics. Yet, there are some issues holding back this technology from becoming the next big thing. As these systems try to accomplish critical elements towards the development of a complete micro-total-analysis systems (μTAS) such as integration of multiple fluidic and analytical steps, sample preparation, and other enabling technologies, the complexity behind the engineering of these systems increase greatly.

So…what is a Sony Discman CD microfluidics?

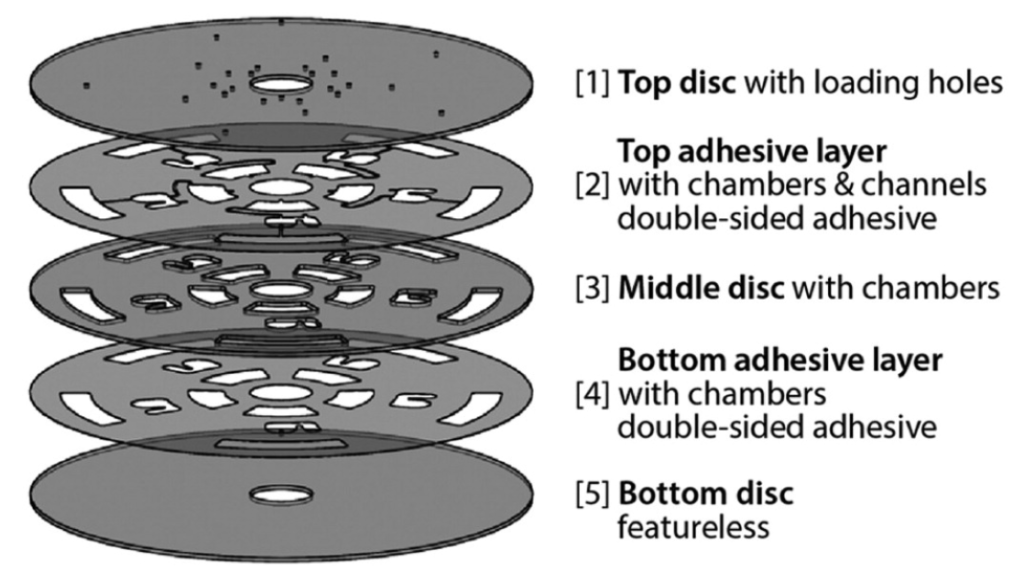

Figure 1: Example five-layer disc assembly. Layers 1,3 and 5 are commonly hard-plastic. Layers 2,4 and double-sided pressure sensitive adhesives (PSAs). Credit: Ling X. Kong2

CD microfluidics uses centrifugal, Coriolis, and Euler forces with respect to a rotating frame of reference to handle fluid-flow2. The main driving force behind fluid flow is the centrifugal force which moves the fluid radially outward from the center of the disc. This unidirectional nature of fluid flow is one of the main disadvantages of CD microfluidics2. Ample research has been and is still being conducted to be able to control and manipulate fluid flow in manners that are essential to services and devices necessary in the healthcare system. Examples of fluid control include valving, pumping, and mixing; all of which are important for sequencing the different fluidic processes3. However, these solutions to the unidirectional disadvantage come at a cost of difficulty in manufacturing and assembly that can hinder implementation of these operations in commercial products.

A five-layer disc assembly shown in Fig. 1 highlights a few of the associated difficulties. Layers 1, 3 and 5 are commonly made from a hard-plastic material while layers 2 and 4 are typically double-sided pressure sensitive adhesives (PSAs)2. Channels and chambers used in the design occupy different layers to maximize the working area because of the small real estate found in CD microfluidics. Furthermore, as layers increase, complications in the assembly of these disks increase significantly as each layer must be aligned properly and adequate adhesion between layers must be ensured to prevent unexpected leakage. Typically, in research labs, disks are made by CNC machining which can lead to long turn-around times and become costly. Ideally, in a commercial setting, CD microfluidic discs should be made using injection molding techniques to ensure consistency, repeatability, and a low-cost per unit. However, intricate designs commonly found on μTASs capable of complex services such as PCR or electrochemical detection may be limited in their ability to be manufactured using injection molding.

Figure 2: Representation of the Lab-on-Disc device showing four parallel tests and the respective components indicating lysis, clarification, PCR amplification, exonuclease reaction, microarray hybridization and washing functions. Credit: Emmanuel Roy4

Regardless, CD microfluidic systems have made a great leap in potential applications because of the developments in fluid control and manipulation and manufacturing techniques. For example, in 2014 Roy et Al. presented an all-thermoplastic integrated sample-to-answer centrifugal microfluidic Lab-on-Disc (LoD) system for nucleic acid analysis. The complete assay comprised cellular lysis, polymerase chain reaction (PCR) amplification, amplicon digestion, and microarray hybridization on a plastic support all of which are shown in Fig. 24. Another example presented by Mishra et Al. describes the automation of a multi-analyte prostate cancer biomarker immunoassay panel from the whole blood5. These two cases highlight the potential of CD microfluidics as viable alternatives to existing techniques in the healthcare system.

Outlook and Conclusion

As researchers slowly move from an emphasis on the development of fluid control and manipulation techniques to the engineering of complete CD microfluidic systems, better substitute solutions will eventually be developed. It is only a matter of time before microfluidic technologies become a standard in the healthcare industry. While there is still much to be done to optimize these systems for commercialization, the growing market for microfluidic devices in North America and globally will fuel the research and development to bring the proof-of-concept devices to market. Future challenges of CD microfluidics include the integration of electrochemical sensors and the development of entire systems capable of complete automation. While costs associated with assays, typically costly in larger scale systems, are decreased because of the smaller volumes used in microfluidics; integrated electrochemical sensors or optical sensors could potentially further decrease costs per use of future systems. As someone who is barely starting a career in this field, it is an exciting and very fortunate opportunity to be a part of what could revolutionize the healthcare industry.

1. ltd, Research and Markets. “North America Microfluidics Market Analysis, Companies Profiles, Size, Share, Growth, Trends and Forecast to 2025.” Research and Markets – Market Research Reports – Welcome, Mar. 2018, www.researchandmarkets.com/research/rmtjrf/north_america?w=4.

2. Kong, Ling X., et al. “Lab-on-a-CD: A Fully Integrated Molecular Diagnostic System.” Journal of Laboratory Automation, vol. 21, no. 3, 2016, pp. 323–355., doi:10.1177/2211068215588456.

3. Gilmore, Jordon, et al. “Challenges in the Use of Compact Disc-Based Centrifugal Microfluidics for Healthcare Diagnostics at the Extreme Point of Care.” Micromachines, vol. 7, no. 4, 2016, p. 52., doi:10.3390/mi7040052.

4. Roy, Emmanuel, et al. “From Cellular Lysis to Microarray Detection, an Integrated Thermoplastic Elastomer (TPE) Point of Care Lab on a Disc.” Lab on a Chip, vol. 15, no. 2.

5. Mishra, Rohit, et al. “Automation of Multi-Analyte Prostate Cancer Biomarker Immunoassay Panel from Whole Blood by Minimum-Instrumentation Rotational Flow Control.” Sensors and Actuators B: Chemical, vol. 263, 2018, pp. 668–675., doi:10.1016/j.snb.2018.02.015., 2015, pp. 406–416., doi:10.1039/c4lc00947a.

Enjoyed this article? Don’t forget to share.

Adrian Bahani

Adrian Bahani is a junior Biomedical Engineering undergraduate student at the University of California, Irvine. He was an undergraduate researcher under Dr. Marc Madou for one year focusing on 3D manufacturing techniques for rapid prototyping of CD-like microfluidic platforms. He currently is an undergraduate researcher at the Beckman Laser Institute in Irvine focusing on developing techniques for high-resolution 3-dimensional visualization of neuro-microvasculature and microbleed formation in the brain. He also leads the largest automotive enthusiast club in the University of California system and can be found wrenching on cars on the weekends.