05 Jul Unveiling the Secrets of Anisotropic Gold Nanoparticle Growth in Microfluidic Reactors

Nanotechnology plays a crucial role in various fields, from medicine to electronics, offering opportunities for groundbreaking applications. One of the key areas of interest is the synthesis of nanoparticles with precise control over their properties which is an ideal fit for microfluidics technology. In this regard, researchers have made significant progress in developing novel methods for synthesizing anisotropic gold nanoparticles (AuNPs) using microfluidic devices. These microfabricated devices provide a platform for precise control of reaction parameters and offer unique advantages over traditional batch synthesis methods.

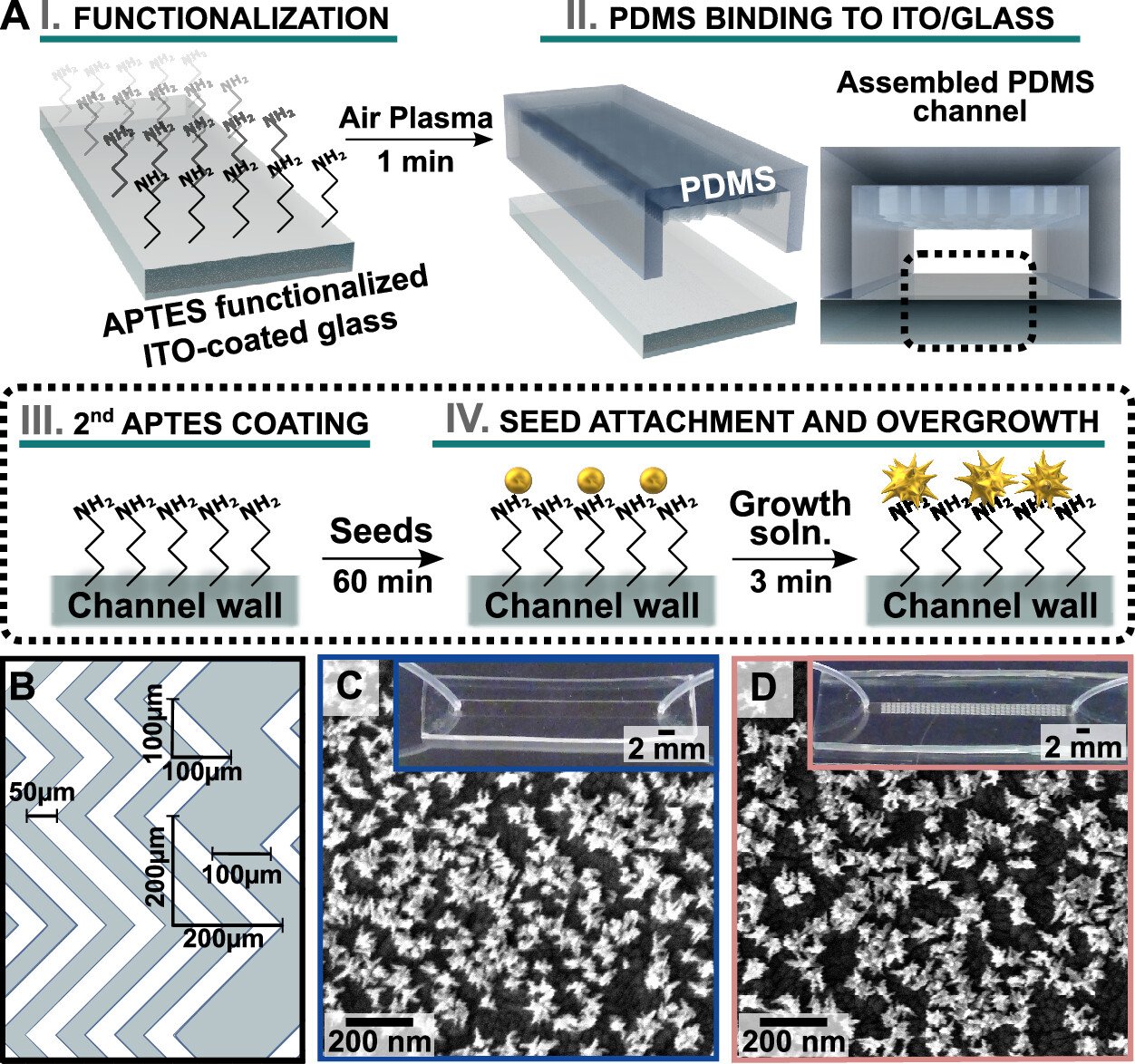

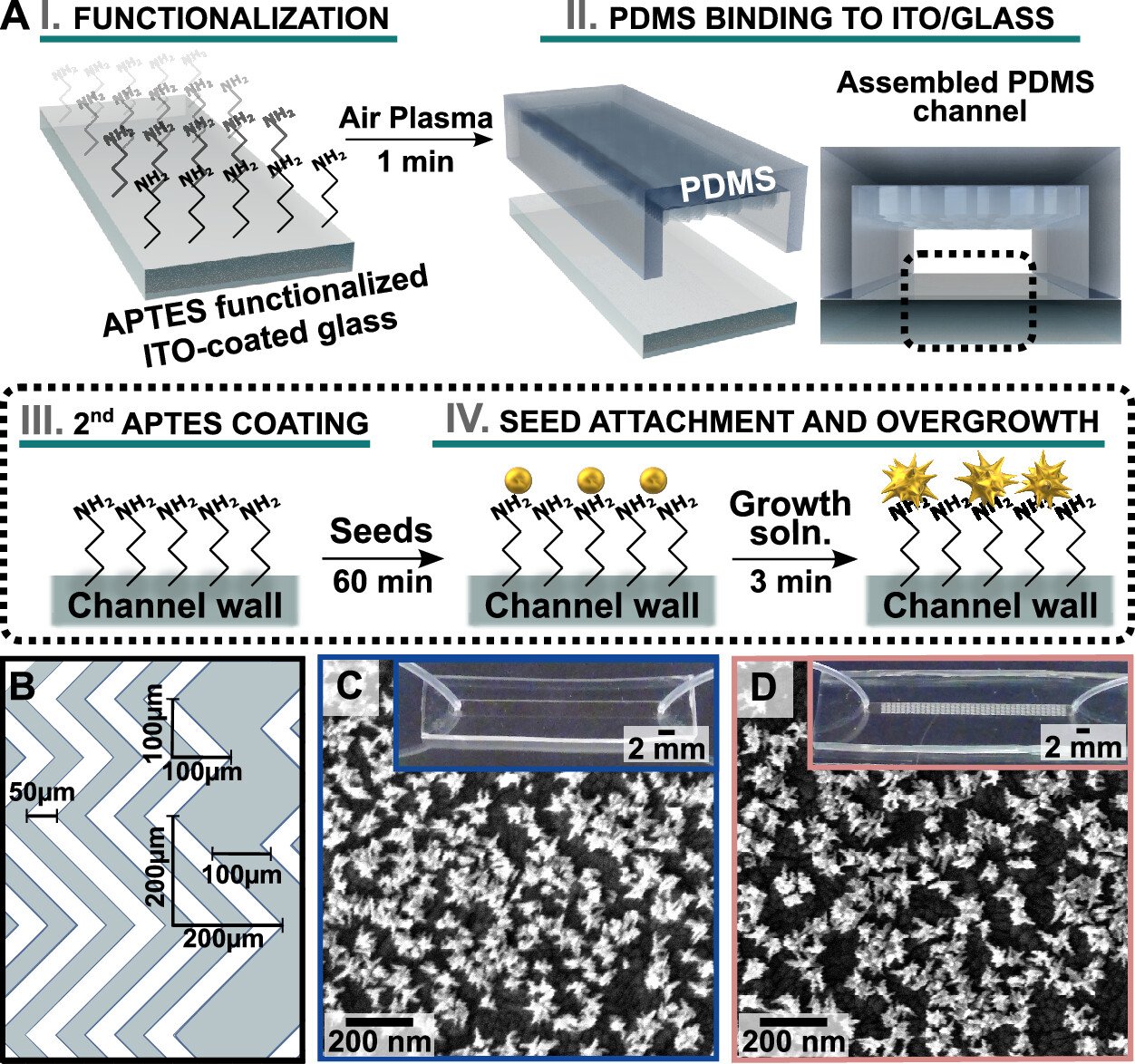

A recent study published in a ACS Applied Nano Materials presents an unconventional seed-mediated in situ synthetic method for the growth of gold nanostars directly on the internal walls of microfluidic chips. The researchers explored the impact of flow rate and profile in the microfluidic chips on reagent consumption, product morphology, and density. This innovative approach allows for the creation of shape gradients and the incorporation of multiple morphologies within the same microreactor, which is challenging to achieve with traditional self-assembly methods.

“Figure 1. (A) Schematic showing (I) functionalization of indium tin oxide (ITO)-coated glass with (3-aminopropyl)triethoxysilane (APTES) adhesion layer to facilitate binding of a polydimethylsiloxane (PDMS) channel for assembly of the microfluidic devices (II). After channel fabrication, (III) a second APTES coating was applied to provide amine moieties for (IV) anchoring gold colloidal seeds to the growth surface and directing overgrowth at the substrate to produce anisotropic gold nanostar structures when a growth solution containing gold, ascorbic acid, and shape-directing reagents was flowed into the channels. (B) Diagram of the herringbone (HB) structure. White represents raised areas of the PDMS (h = 50 μm, total channel height = 90 μm). (C,D) Scanning electron microscopy images of nanostars on ITO synthesized in (C) featureless and (D) HB channels. Insets: Digital photographs of the microfluidic chips.” Reproduced from Gail A. Vinnacombe-Willson, Joy K. Lee, Naihao Chiang, Leonardo Scarabelli, Shouzheng Yue, Ruth Foley, Isaura Frost, Paul S. Weiss, and Steven J. Jonas ACS Applied Nano Materials 2023 6 (8), 6454-6460 under Creative Commons Attribution 4.0 International License.

Plasmonic nanostructures play a crucial role in on-chip platforms that require light-triggered heating, hot electron catalysis, and enhanced localized electromagnetic fields. The ability to precisely control the composition, morphology, and surface chemistry of plasmonic nanoparticles is paramount for their application in cancer diagnostics, chemical and biological sensing, anticounterfeiting, and microreactors. The research showcased in this study leverages bottom-up chemical synthesis and in situ growth to simplify fabrication processes, improve coating density, and enhance the versatility of plasmonic-microfluidic platforms. The implications extend to a wide range of fields, including cell culture and sorting, catalysis, sensing, and drug/gene delivery.

One of the intriguing aspects of this research is the identification of flow-limited growth as a dominant mechanism for the synthesis of anisotropic gold nanoparticles. The flow rate within microfluidic channels significantly influences the growth process. Varying flow rates result in different product morphologies and density, and the researchers also observed the formation of color gradients along the channels. This discovery opens up new avenues for the controlled synthesis of nanoparticles with tailored properties for specific applications.

The study also explored the impact of microreactor design on nanoparticle growth. Specifically, the researchers utilized polydimethylsiloxane (PDMS) “herringbone” (HB) chaotic mixers with 3D staggered features. These microreactors provide chaotic flows that are advantageous for particle and cell sorting, as well as for promoting reagent and heat exchange. The HB geometry facilitated the creation of different growth patterns and enhanced control over product size, density, and surface coverage. The findings highlight the importance of microreactor design in achieving reproducible and uniform coatings of anisotropic nanoparticles.

The research on the growth of anisotropic gold nanoparticles in microfluidic reactors paves the way for further investigations and applications. Future studies could delve deeper into the relationship between nanoparticle size, density, and morphology. Crystallographic characterization techniques, such as high-resolution electron microscopy, could provide valuable insights into the structural properties of the nanoparticles. Additionally, the integration of these thermoplasmonic nanoparticles into microfluidic systems holds immense potential for various fields, enabling advancements in cell isolation/sorting, chemical/biological sensing, drug delivery/screening, and catalysis.

In conclusion, the exploration of the growth of anisotropic gold nanoparticles within microfluidic reactors represents a significant advancement in nanoparticle synthesis. The ability to control and manipulate the growth process offers unprecedented opportunities for creating shape gradients, multifunctional coatings, and tailored properties for diverse applications. This research brings us one step closer to harnessing the full potential of nanotechnology in various fields, transforming the way we approach diagnostics, sensing, and therapeutics.

“Ultimately, we lay the groundwork for the straightforward fabrication of complex thermoplasmonic nanoparticle-integrated microfluidic systems that incorporate chaotic flows, which can be broadly applied for cell isolation/sorting, chemical/biological sensing, drug delivery/screening, and catalysis. “, the authors explained.

Figures are reproduced from Gail A. Vinnacombe-Willson, Joy K. Lee, Naihao Chiang, Leonardo Scarabelli, Shouzheng Yue, Ruth Foley, Isaura Frost, Paul S. Weiss, and Steven J. Jonas ACS Applied Nano Materials 2023 6 (8), 6454-6460 DOI: 10.1021/acsanm.3c00440.

Read the original article: Exploring the Bottom-Up Growth of Anisotropic Gold Nanoparticles from Substrate-Bound Seeds in Microfluidic Reactors