04 Feb Bridging Nature and Technology: Precision Engineering of Spider Silk with Microfluidics

The marvel of spider silk, with its unmatched strength, elasticity, and biodegradability, has long captivated scientists and engineers. The quest to synthesize spider silk outside of its natural context has faced numerous challenges, primarily due to the complex molecular processes involved. However, a groundbreaking study has recently made significant strides by leveraging microfluidics technology, particularly through the development of a microfluidic chip to mimic the natural silk-spinning processes of spiders.

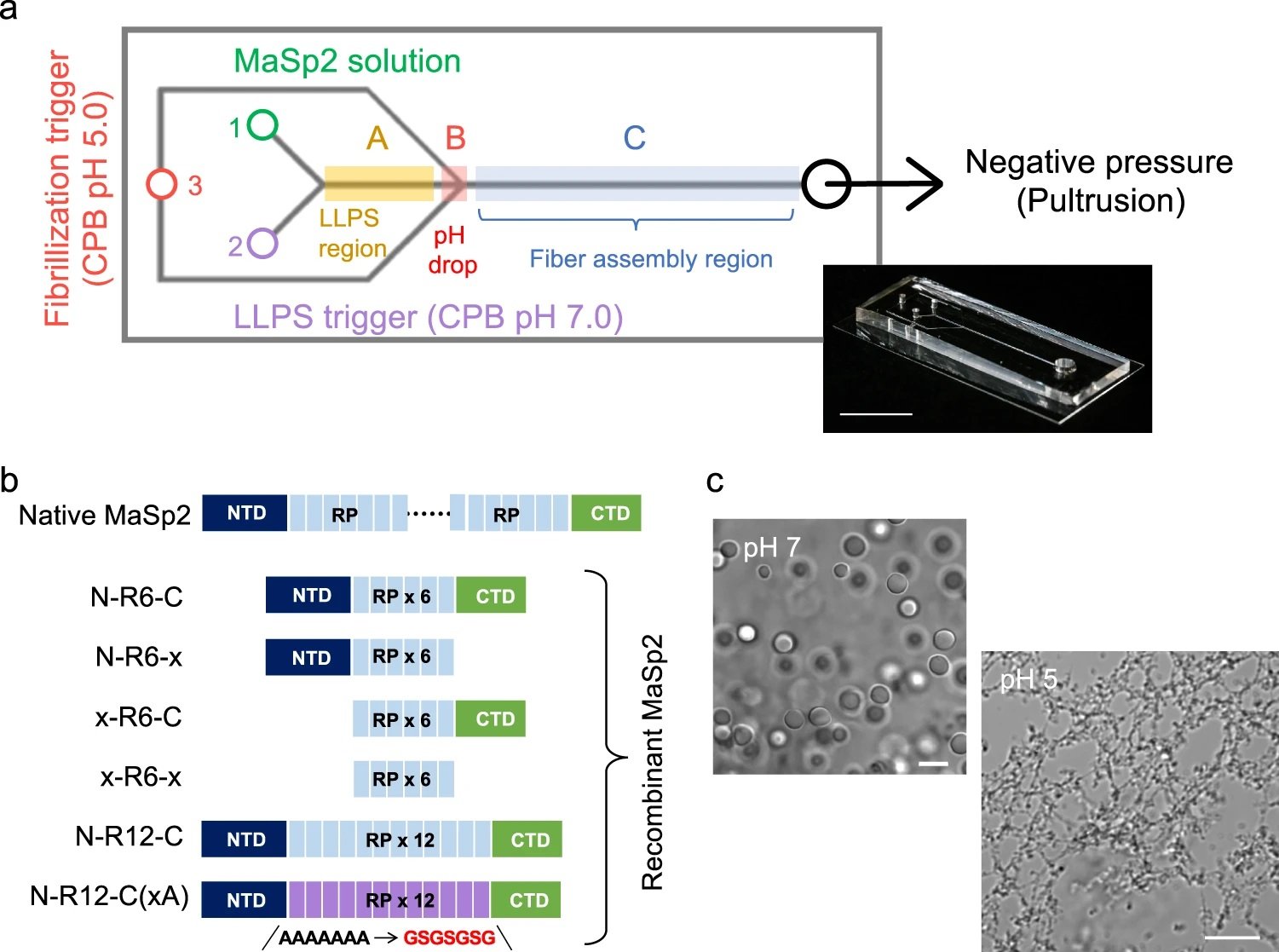

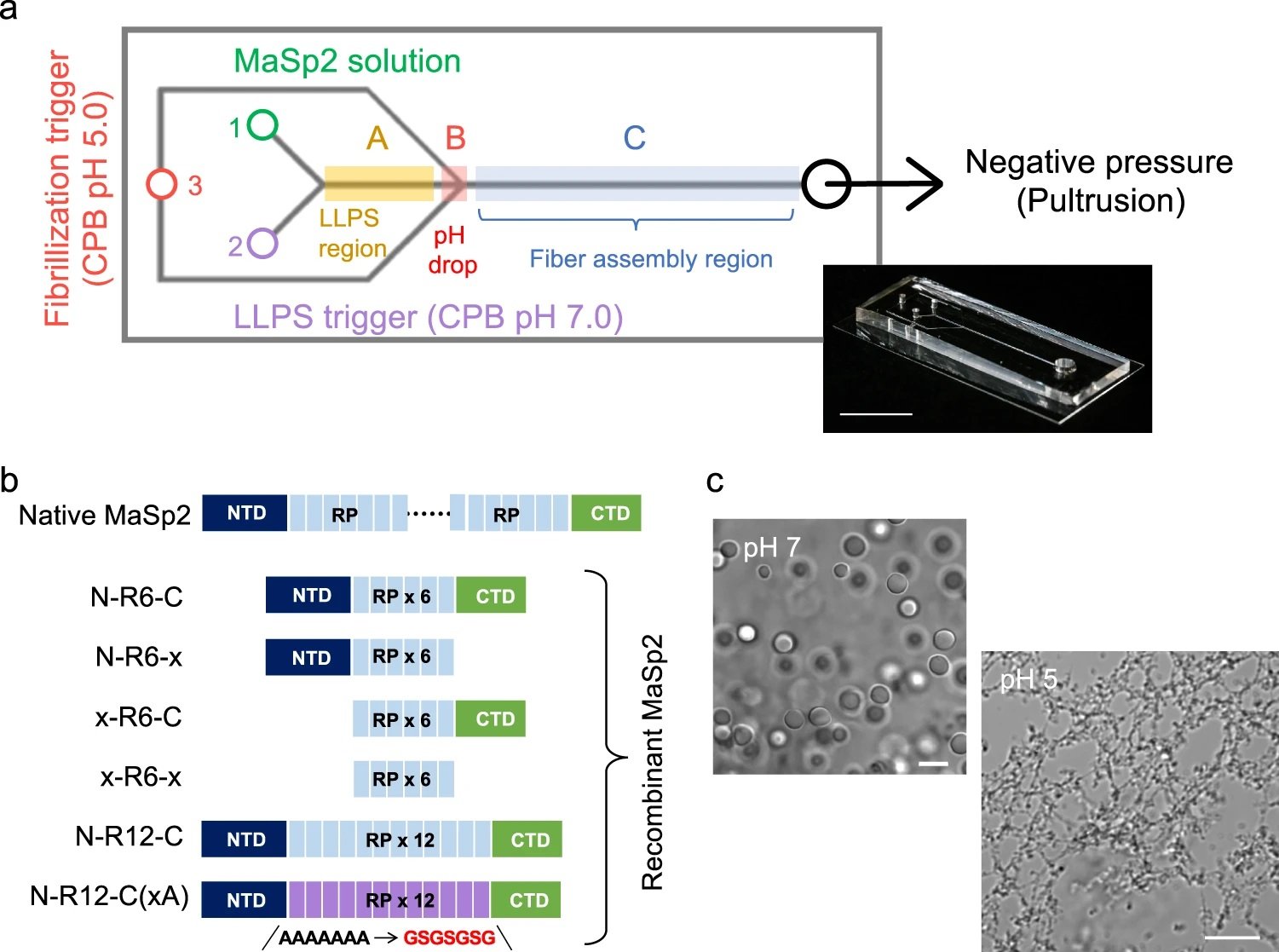

“In this study, we use a microfluidic device to create continuous fibers based on recombinant MaSp2 spidroin. The strategy incorporates ion-induced liquid-liquid phase separation, pH-driven fibrillation, and shear-dependent induction of β-sheet formation.“, the authors explained.

Central to this study is a PDMS microfluidic device, meticulously engineered through advanced microfluidic fabrication techniques, designed to replicate the environmental nuances of a spider’s silk gland. This microfluidic chip meticulously controls the flow and mixing of silk protein solutions under precise conditions, facilitating a biomimetic pathway for silk fiber formation. Through the application of shear forces and the creation of biomimetic chemical gradients, the microfluidic system initiates the transition from a liquid-liquid phase separation (LLPS) to nanofibrillation, ultimately resulting in the formation of silk fibers with hierarchical structural properties akin to those found in nature. The experimental setup varied shear in order to find the optimal rate, where silk proteins exhibited a marked increase in alignment and crystallization, akin to natural silk fiber production processes.

The silk fibers produced under these optimized microfluidic conditions showed remarkable similarities to natural spider silk in terms of structure and mechanical properties. The application of a shear rate enabled the production of fibers that not only replicate the hierarchical organization of natural spider silk but also begin to approach its tensile strength and elasticity. The fibers produced had diameters ranging from 5 to 10 µm while maintaining the hierarchical substructure of the fiber throughout the length of the channel.

“a Layout of the microfluidic device, consisting of three inlets and one outlet with a negative pressure controlling system. The spidroin was first mixed with 50 mM CPB at pH 7 and then subjected to 1 M citrate–phosphate buffer (CPB) (pH 5) at the intersection. The channel along which MaSp2 assembled was divided into sections A, B and C for comparison in terms of the morphology and secondary structure. The inset shows a picture of the actual microfluidic device. Scale bar, 1 cm. b The different recombinant MaSp2 constructs used in this study, representing various combinations of the N-terminal domain (NTD), repeat (RP) and C-terminal domain (CTD). For N-R12-C(xA), the poly-Ala repeat normally found in the repetitive region was replaced by GSGSGSG. c N-R12-C in the form of droplets and nanofibrils obtained by exposure to 0.5 M CPB at pH 7 and 5, respectively. Five independent experiments were performed with similar results. Scale bar, 5 μm.” Reproduced from Chen, J., Tsuchida, A., Malay, A.D. et al. Replicating shear-mediated self-assembly of spider silk through microfluidics. Nat Commun 15, 527 (2024). https://doi.org/10.1038/s41467-024-44733-1 under a CC BY 4.0 DEED Attribution 4.0 International license.

The successful replication of spider silk using microfluidic technology opens the door to a new era of materials science, where the fusion of biological principles and engineering ingenuity holds the promise of creating sustainable, high-performance materials. This study serves as a blueprint for future research, suggesting that with further refinement, it may be possible to achieve even closer approximations of natural spider silk’s mechanical properties, as well as to apply these techniques to a broad array of biomaterials.

“In summary, by using a microfluidic device, we report a biomimetic strategy in probing the β-sheet development under native-like assembly process from LLPS to nanofibrillization to hierarchically organized fiber. This work provides a basis for the rational design of biomimetic spinning with regard to domain structure, microfluidic fabrication, shear threshold and hierarchical reconstruction. “, the authors concluded.

For more insights into the world of microfluidics and its burgeoning applications in biomedical research, stay tuned to our blog and explore the limitless possibilities that this technology unfolds. If you need high quality microfluidics chip for your experiments, do not hesitate to contact us.

Figures are reproduced from Chen, J., Tsuchida, A., Malay, A.D. et al. Replicating shear-mediated self-assembly of spider silk through microfluidics. Nat Commun 15, 527 (2024). https://doi.org/10.1038/s41467-024-44733-1 under a CC BY 4.0 DEED Attribution 4.0 International license.

Read the original article: Replicating shear-mediated self-assembly of spider silk through microfluidics