19 May Microcurved culture membranes: A step forward towards more organ-on-a-chip physiological realism

Abstract

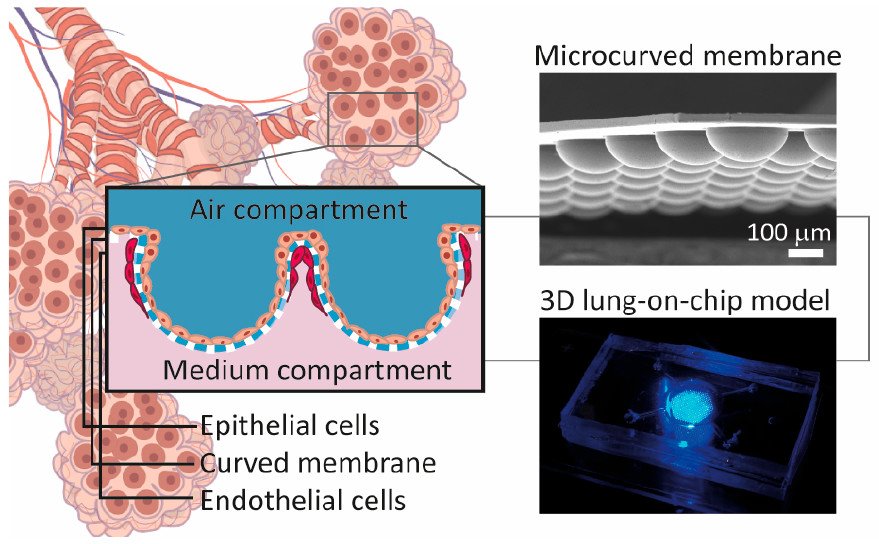

“A comparatively straightforward approach to accomplish more physiological realism in organ-on-a-chip (OoC) models is through substrate geometry. There is increasing evidence that the strongly, microscale curved surfaces that epithelial or endothelial cells experience when lining small body lumens, such as the alveoli or blood vessels, impact their behavior. However, the most commonly used cell culture substrates for modeling of these human tissue barriers in OoCs, ion track-etched porous membranes, provide only flat surfaces. Here, we propose a more realistic culture environment for alveolar cells based on biomimetically microcurved track-etched membranes. They recreate the mainly spherical geometry of the cells’ native microenvironment. In this feasibility study, the membranes were given the shape of hexagonally arrayed hemispherical microwells by an innovative combination of three-dimensional (3D) microfilm (thermo)forming and ion track technology. Integrated in microfluidic chips, they separated a top from a bottom cell culture chamber. The microcurved membranes were seeded by infusion with primary human alveolar epithelial cells. Despite the pronounced topology, the cells fully lined the alveoli-like microwell structures on the membranes’ top side. The confluent curved epithelial cell monolayers could be cultured successfully at the air−liquid interface for 14 days. Similarly, the top and bottom sides of the microcurved membranes were seeded with cells from the Calu-3 lung epithelial cell line and human lung microvascular endothelial cells, respectively. Thereby, the latter lined the interalveolar septum-like interspace between the microwells in a network-type fashion, as in the natural counterpart. The coculture was maintained for 11 days. The presented 3D lung-on-a-chip model might set the stage for other (micro)anatomically inspired membrane-based OoCs in the future.”

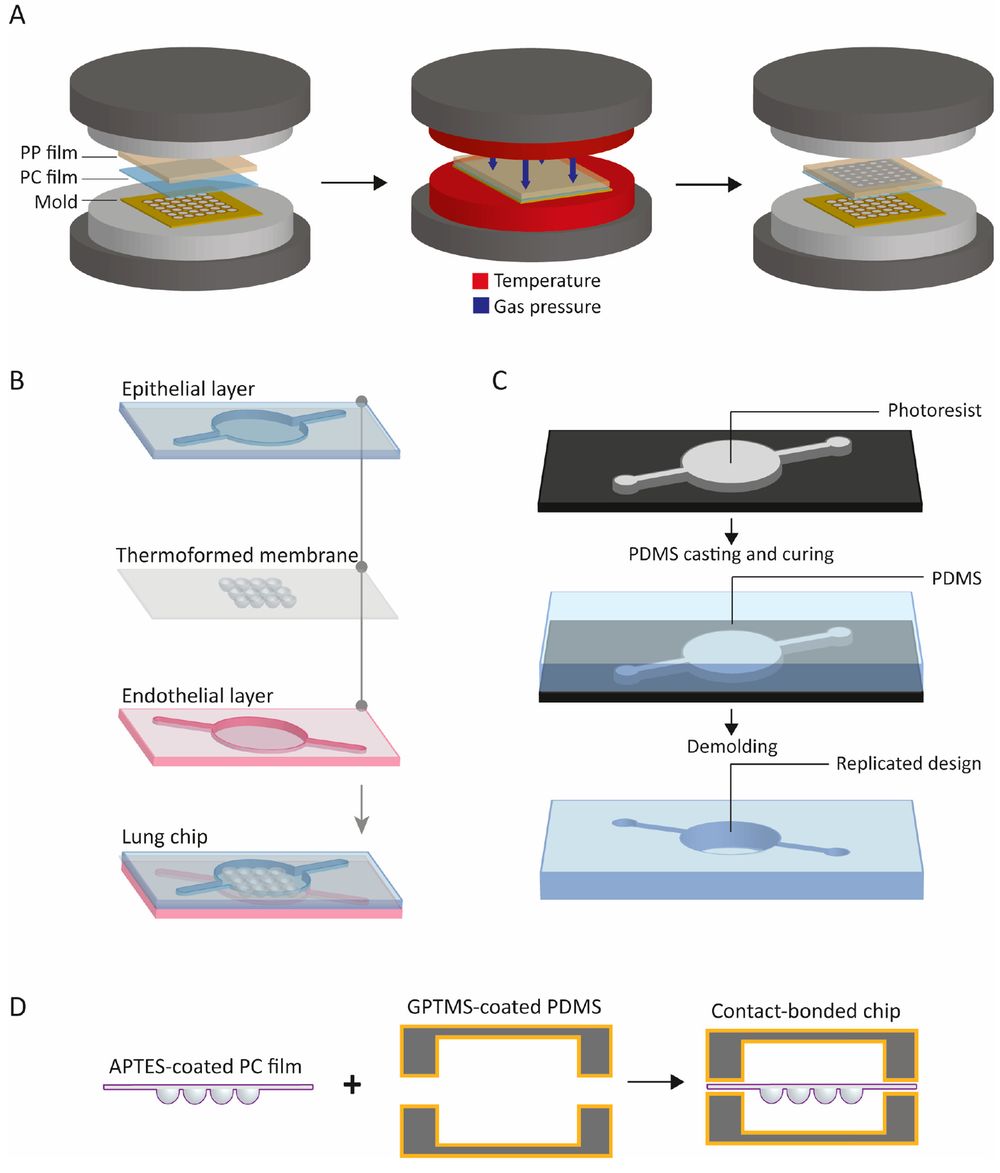

“Microfabrication of the 3D lung-on-chip device. (A) Fabrication of the biomimetically microcurved culture membrane by thermoforming. An additional (dense) PP sealing film allows the micro pressure (thermo)forming of the porous PC film/membrane using compressed nitrogen. (B) Microfluidic chip construction and design. The OoC device consists of a top and a bottom housing half from polydimethylsiloxane (PDMS) containing microfluidic structures and the biomimetic membrane sandwiched in between. (C) Fabrication of the housing halves of the PDMS chip body by casting of the PDMS precursor over an SU-8-silicon mold, curing of the precursor, and peeling off the structured PDMS layer. (D) Assembly and chemical−thermal bonding of the housing halves and the microcurved membrane.” Reproduced under Creative Commons Attribution 4.0 International License from Danielle Baptista, Liliana Moreira Teixeira, et al., ACS Biomaterials Science & Engineering Article ASAP DOI: 10.1021/acsbiomaterials.1c01463. Sci Rep 12, 7392 (2022).

Figures and the abstract are reproduced from Danielle Baptista, Liliana Moreira Teixeira, et al., ACS Biomaterials Science & Engineering Article ASAP DOI: 10.1021/acsbiomaterials.1c01463. Sci Rep 12, 7392 (2022) under Creative Commons Attribution 4.0 International License.

Read the original article: 3D Lung-on-Chip Model Based on Biomimetically Microcurved Culture Membranes