20 Sep Microfluidic occlusive thrombosis-on-a-chip can be used to monitor the effect of antithrombotic drugs

Myocardial infarction, commonly known as heart attack, causes a majority of cardiovascular disease (CVD) deaths which can be triggered by occlusion of the arteries. Finding new drugs to fight myocardial infractions requires accurate modelling of the process. In a recent article published in the lab on a chip journal, a research team employs microfluidics to develop an accurate in vitro model for the clot formation process. The proposed microfluidic chip can be used to determine the occlusion time and is envisioned to be used for developing new antithrombotic drugs.

Abstract

“Cardiovascular disease remains one of the world’s leading causes of death. Myocardial infarction (heart attack) is triggered by occlusion of coronary arteries by platelet-rich thrombi (clots). The development of new anti-platelet drugs to prevent myocardial infarction continues to be an active area of research and is dependent on accurately modelling the process of clot formation. Occlusive thrombi can be generated in vivo in a range of species, but these models are limited by variability and lack of relevance to human disease. Although in vitro models using human blood can overcome species-specific differences and improve translatability, many models do not generate occlusive thrombi. In those models that do achieve occlusion, time to occlusion is difficult to measure in an unbiased and objective manner. In this study we developed a simple and robust approach to determine occlusion time of a novel in vitro microfluidic assay. This highlighted the potential for occlusion to occur in thrombosis microfluidic devices through off-site coagulation, obscuring the effect of anti-platelet drugs. We therefore designed a novel occlusive thrombosis-on-a-chip microfluidic device that reliably generates occlusive thrombi at arterial shear rates by quenching downstream coagulation. We further validated our device and methods by using the approved anti-platelet drug, eptifibatide, recording a significant difference in the “time to occlude” in treated devices compared to control conditions. These results demonstrate that this device can be used to monitor the effect of antithrombotic drugs on time to occlude, and, for the first time, delivers this essential data in an unbiased and objective manner.”

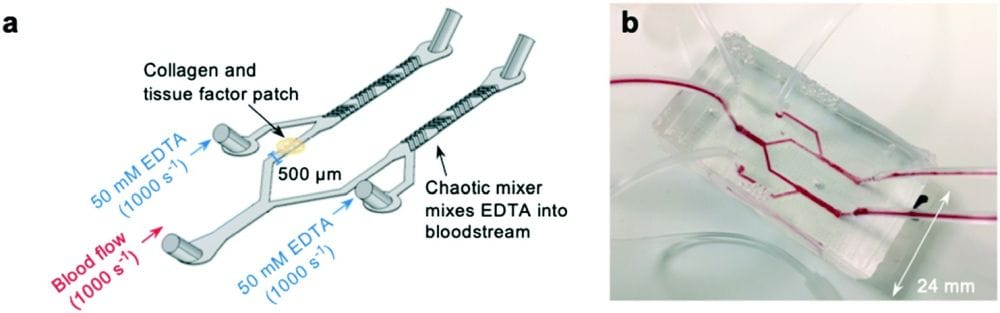

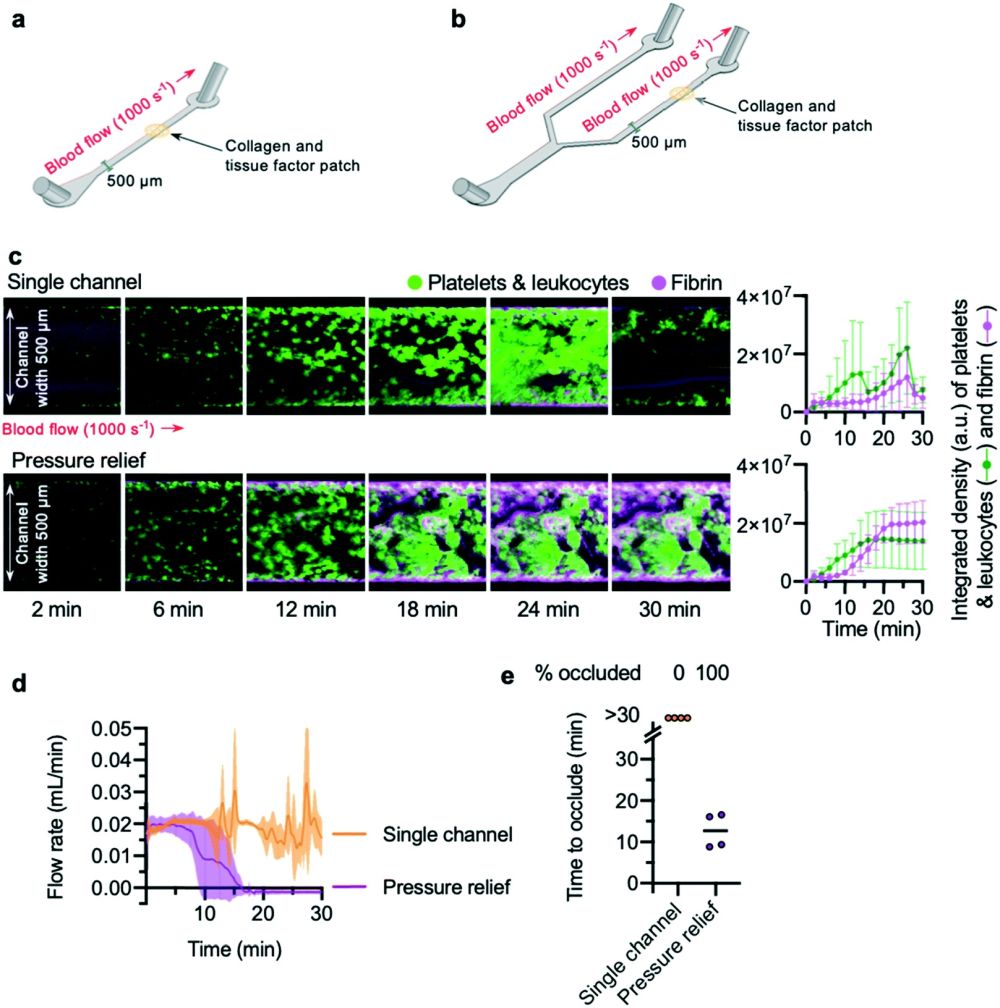

The working mechanism of the microfluidic device

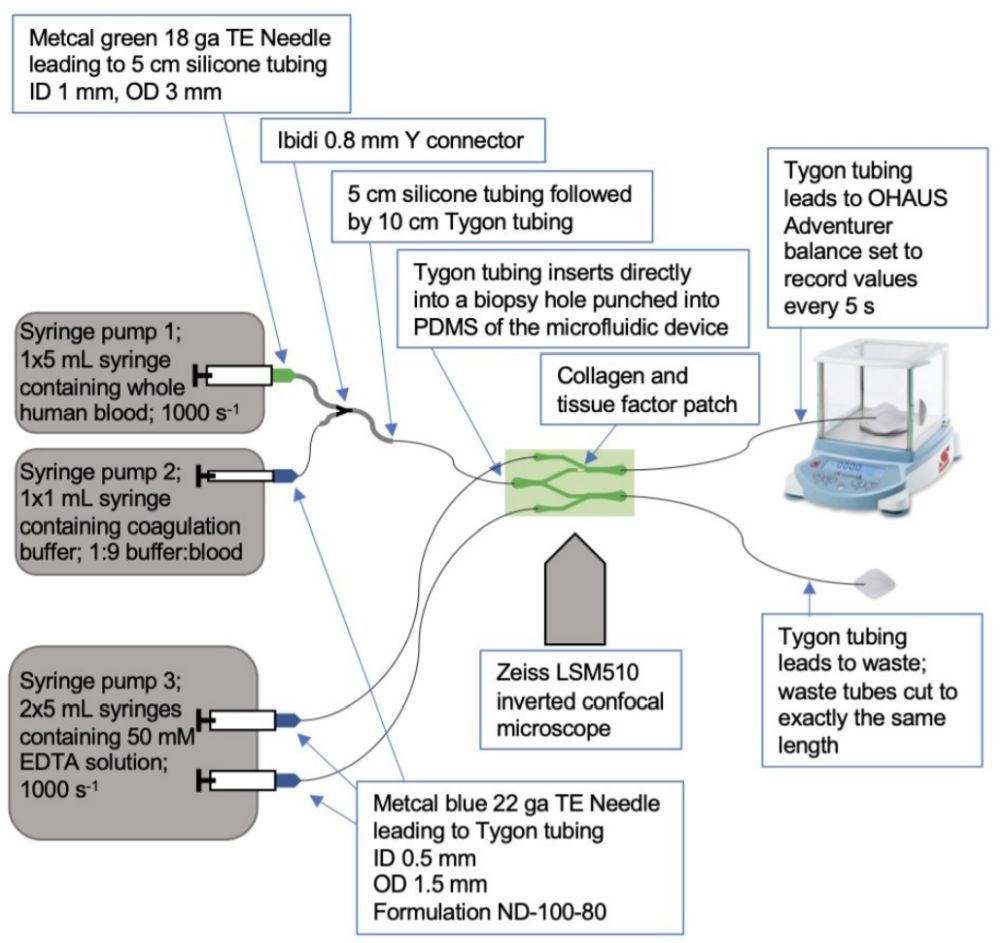

Conventional soft/photolithography techniques were used to microfabricated the microfluidic chips. Two different microfluidic chips were designed to measure the time to occlude. A “single channel” microfluidic chip which included a simple channel connected to an outlet and a “pressure relief” microfluidic chip in which the single channel branches to two outlets. In the “single channel” microfluidic device, a patch of collagen and tissue factor was placed onto a slide first. Then the slide was positioned upstream of the microchannel. For the “pressure relief” microfluidic device, however, the slide was positioned in the center of one of the arms. A vacuum channel was placed around the microfluidic chip that was separate from the rest of the device. By applying negative pressure to this vacuum microchannel a reversible bonding was achieved and the device was sealed.

Reproduced under Attribution 3.0 Unported (CC BY 3.0) License from J. Berry, F. J. Peaudecerf, N. A. Masters, K. B. Neeves, R. E. Goldstein and M. T. Harper, Lab Chip, 2021, Advance Article , DOI: 10.1039/D1LC00347J.

The microfluidic chips were perfused with Citrate-anticoagulated whole blood, recalcified by a buffer added to the blood. The flow rate was adjusted to result in a shear rate comparable to that of The occlusion formation was then visualized by labelling the platelets.

Reproduced under Attribution 3.0 Unported (CC BY 3.0) License from J. Berry, F. J. Peaudecerf, N. A. Masters, K. B. Neeves, R. E. Goldstein and M. T. Harper, Lab Chip, 2021, Advance Article , DOI: 10.1039/D1LC00347J.

“Our device could be readily modified to include further disease relevant features, such as different pro-thrombotic substrates or stenotic channel geometries. In time, we hope that such devices will replace many of the in vivo experiments currently performed in thrombosis research.”, the authors concluded.

Read the original article: An “occlusive thrombosis-on-a-chip” microfluidic device for investigating the effect of anti-thrombotic drugs

Pouriya Bayat

Pouriya is a microfluidic production engineer at uFluidix. He received his B.Sc. and M.A.Sc. both in Mechanical Engineering from Isfahan University of Technology and York University, respectively. During his master's studies, he had the chance to learn the foundations of microfluidic technology at ACUTE Lab where he focused on designing microfluidic platforms for cell washing and isolation. Upon graduation, he joined uFluidix to even further enjoy designing, manufacturing, and experimenting with microfluidic chips. In his free time, you might find him reading a psychology/philosophy/fantasy book while refilling his coffee every half an hour. Is there a must-read book in your mind, do not hesitate to hit him up with your to-read list.