27 Aug High throughput bioinspired microfluidic chip for particle filtration

Nature has always been a source of inspiration for us. Over years and years, nature has developed highly efficient mechanisms in living organisms that can light the way for designers and engineers. In this week’s research highlight, we are going to introduce a microfluidic chip inspired by the filtration mechanism of manta ray for ultrahigh throughput filtration. In this paper published in the Lab on a chip journal, researchers from North Carolina State University developed a bioinspired microfluidic device for particle filtration that is capable of operating at 20 ml/min with a filtration efficiency of 99%.

Abstract

“Size-based microfluidic filtration systems can be affected by clogging, which prevents their use in high-throughput and continuous applications. To address these concerns, we have developed two microfluidic lobe filters bioinspired by the filtration mechanism of two species of manta ray. These chips enable filtration of particles around 10–30 μm with precise control and high throughput by using two arrays of equally spaced filter lobes. For each filter design, we investigated multiple inlet flow rates and particle sizes to identify successful operational parameters. Filtration efficiency increases with fluid flow rate, suggesting that particle inertial effects play a key role in lobe filter separation. Microparticle filtration efficiencies up to 99% were obtainable with inlet flow rates of 20 mL min−1. Each filter design successfully increased microparticle concentrations by a factor of two or greater at different inlet flow rates ranging from 6–16 mL min−1. At higher inlet flow rates, ANSYS Fluent simulations of each device revealed a complex velocity profile that contains three local maxima and two inflection points. Ultimately, we show that distances from the lobe array to the closest local maxima and inflection point of the velocity profile can be used to successfully estimate lobe filtration efficiency at each operational flow rate.”

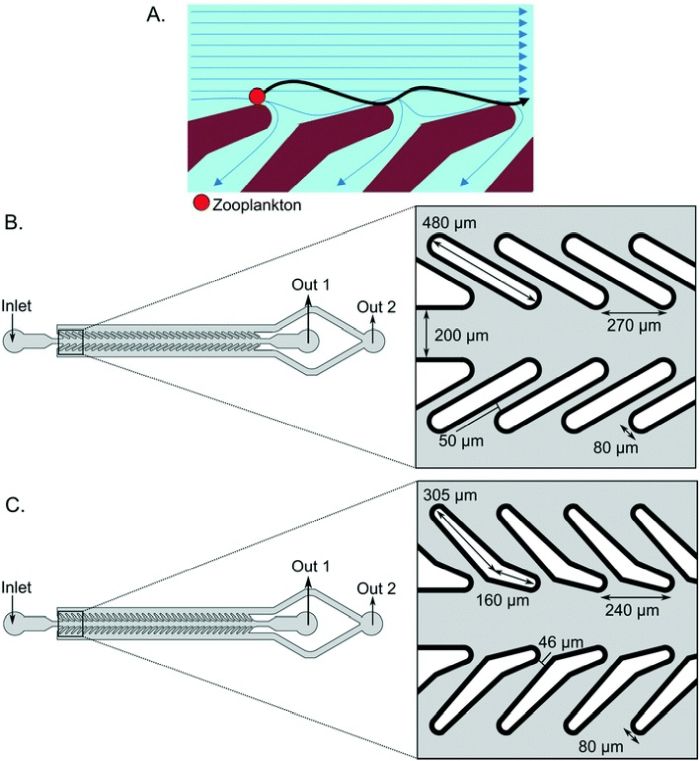

The working mechanism of the microfluidic device

The filtration mechanism was adapted from the lobe filtration of manta rays. This bioinspired microfluidic chip for high throughput filtration is microfabricated with PDMS using conventional microfluidic microfabrication methods. Each device consists of an inlet connected to a microchannel with an array of equally spaced lobes. The lobes can either keep the particles in the center microchannel or guide them to the side channels based on the particle size (see the image below). The microfluidic chips were designed by scaling down measurements of two species namely M. birostris and M. tarapacana (see below). The measurements were scaled down nearly 6 times to target 10-30 micron particles. Each array of lobes contains 31 lobes to ensure sufficient opportunity for filtration.

Reproduced from A. S. Clark and A. San-Miguel, Lab Chip, 2021, Advance Article, DOI: 10.1039/D1LC00449B with permission from Royal Society of Chemistry.

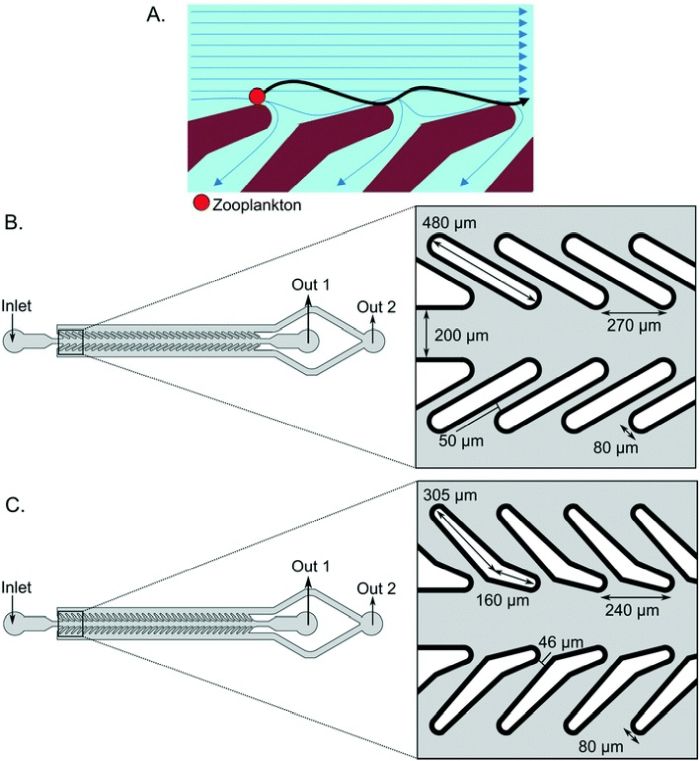

The microfluidic chips were tested with a mix of fluorescent 15 micron and 25 micron particles at various flow rates. The M. birostris and M. tarapacana feed at moderate Reynolds number. The research team hypothesized that the Reynolds number should be similar for successful filtration. Thus, the filtration microfluidic chips were run at a range of fairly high flow rates (up to 20 ml/min) and the filtration efficiencies were characterized based on the particle concentrations collected from the outlets.

Reproduced from A. S. Clark and A. San-Miguel, Lab Chip, 2021, Advance Article, DOI: 10.1039/D1LC00449B with permission from Royal Society of Chemistry.

“As a novel mechanism for microfluidic applications, lobe filtration offers high throughput microparticle filtration with processing speeds up to 20 mL min−1. The high processing speeds open the possibility for various applications in which large volumes of liquid need to be filtered. For example, microplastic removal, which has concentrations of ∼400 parts per L, would otherwise not be possible using a microfluidic device without extensive parallelization.”

Read the original article: A bioinspired, passive microfluidic lobe filtration system

Pouriya Bayat

Pouriya is a microfluidic production engineer at uFluidix. He received his B.Sc. and M.A.Sc. both in Mechanical Engineering from Isfahan University of Technology and York University, respectively. During his master's studies, he had the chance to learn the foundations of microfluidic technology at ACUTE Lab where he focused on designing microfluidic platforms for cell washing and isolation. Upon graduation, he joined uFluidix to even further enjoy designing, manufacturing, and experimenting with microfluidic chips. In his free time, you might find him reading a psychology/philosophy/fantasy book while refilling his coffee every half an hour. Is there a must-read book in your mind, do not hesitate to hit him up with your to-read list.