Microfluidics Techniques and Practices

Microfluidics applications are enabled using many techniques developed by biologists, mechanical engineers, chemists, surface science engineers, electrical engineers, physicists, and many more. Here we present technical articles written by uFluidix scientists, engineers, or technical writers to describe most enabling Microfluidics processes or technologies. Click on each title to read the full article.

Microfluidics Fabrication Notes

- Microfluidic Channels- Practical Design Tips.

- What are Differences Between Prototyping and Manufacturing in Microfluidics Domain?

- Should I Buy Custom PDMS Chips or Fabricate Them Myself?

- Custom Manufacturing is the Method of Choice by Microfluidics Industry. Why?

- Materials for Fabrication of Microfluidic Devices.

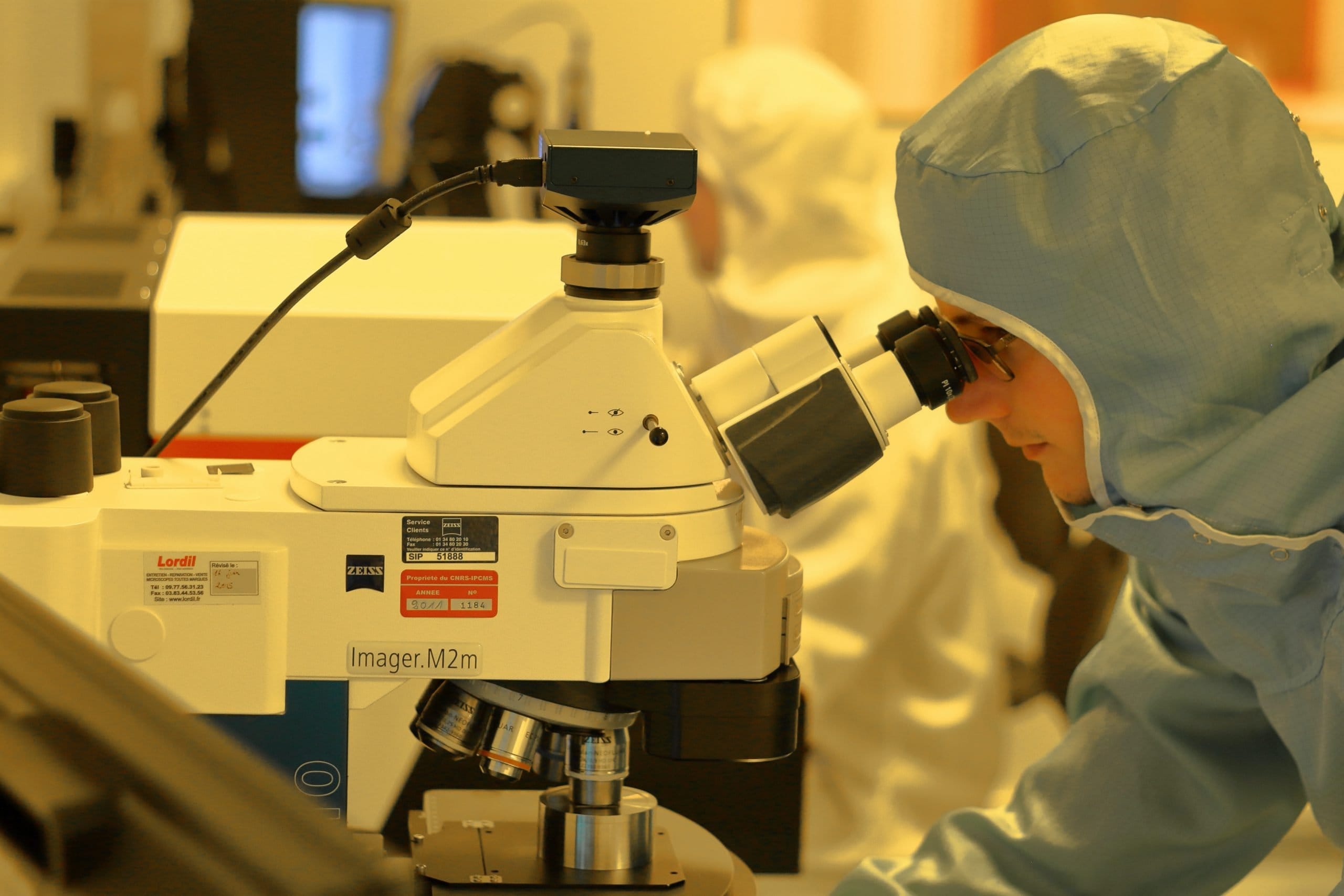

- How to Fabricate Microfluidic Chips?

- What is a Microfluidic Device?

- What is a Microfluidic Chip?

- Tips to Design Manufacturable Microfluidic Chips.

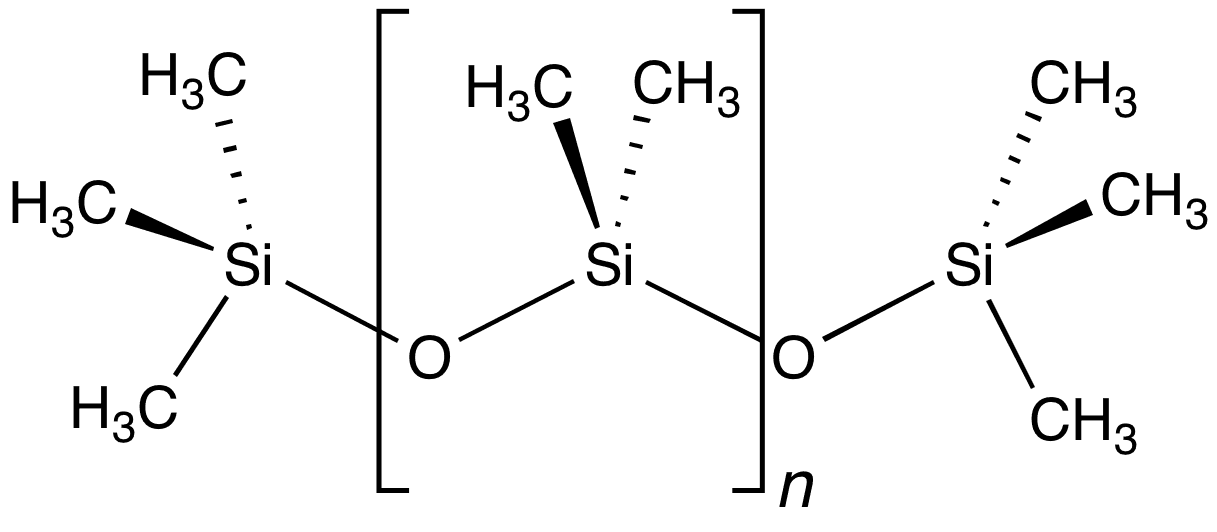

- What is PDMS and How It is Used for Fabrication of Microfluidics?

- How to Modify Surface and bulk Properties of PDMS Chips to Fit Your Application.

- How to Calculate Pressure in Micro-channels?

- How to Avoid Autofluorescence in Microfluidics?

- Limits of 3D printing for manufacturing and fabrication of Microfluidic chips and devices

Technical Tips on How to Use Microfluidic Chips and Set up Experiments

PDMS is the most widely used Material for its best feature resolution. Thermoplastics are also used for the fabrication of Microfluidic chips.

Faster flow rate, and smaller channels cause higher upstream pressure. How High? Calculate here.

PDMS is inherently Hydrophobic. How to modify its hydrophobicity to fit you applications , and more.

Before you decide to fabricate your own PDMS devices or buy them from a custom manufacturer read this article. Would save you Money and Time!

What is the difference in cost, lead time, or technologies for prototyping vs manufacturing Microfluidic devices?

How to describe the geometry of the microfluidic channel in your design. Get practical tips, and avoid popular mistakes!

Despite advantages such as fast creation of 3D structures, 3D printing technology faces many challenges for being used to manufacture microfluidic chips and devices.