29 May Microfluidic bandage for delivery and sensing of oxygen for smart wound healing

A chronic wound also called a non-healing wound is one that has failed to heal in an orderly and timely manner. If the wound does not heal in more than 8 weeks, it is considered a chronic wound. Several factors can contribute to the chronicity of a wound such as oxygen deprivation in the wound. Different wound dressings based on the wound type such as wound oxygenation can accelerate the healing process.

Oxygen is essential for wound healing. Oxygen requirements for tissue regeneration vary and depend on several factors. For example, typically the tissue experiences greater hypoxia at the center of the wound. In the past, a clinician was in charge of visual monitoring of the wound and selection of suitable dressing which is indeed a subjective process and lacks precision. Therefore, a platform that is capable of concurrent measurement and delivery of wound dressings to the tissue can have a significant effect on wound healing. An ideal and smart platform would be able to screen multiple parameters and provide the wound with the proper dressing to boost the healing. Microfluidics can be employed to address these challenges.

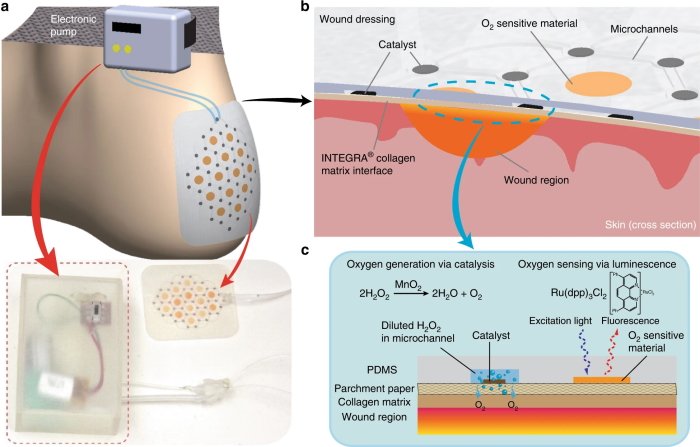

A team of researchers took the first step towards developing a multi-functional smart bandage system for monitoring and healing chronic wounds. A novel microfluidic device is now developed that is capable of sensing and delivery of oxygen for smart wound dressing. The proposed system takes advantage of a PDMS microfluidic chip attached to a sensing and fluid delivery system to precisely monitor the oxygen level at the wound and deliver oxygen on demand. This microfluidic chip for wound healing is reported in a journal article entitled “Integrated sensing and delivery of oxygen for next-generation smart wound dressings” in Microsystems and Nanoengineering journal.

“We developed a low-cost alternative for continuous O2 delivery and sensing comprising of an inexpensive, paper-based, biocompatible, flexible platform for locally generating and measuring oxygen in a wound region. The platform takes advantage of recent developments in the fabrication of flexible microsystems including the incorporation of paper as a substrate and the use of a scalable manufacturing technology, inkjet printing.”

Schematic of the microfluidic platform for wound healing. Reproduced under creative commons license.

The wound healing system consists of a multi-layer flexible microchip. A microfluidic network bonds to a parchment substrated with a functionalized surface. To generate the oxygen for dressing the wound, H2O2 was used due to its clean decomposition and frequent use in clinical settings. 1 mL of H2O2 can degenerate and produce 10mg of O2 according to the stoichiometric ratio. KMnO4 was used as a convenient and simple to synthesize catalyst for decomposing H2O2. The microchannel network delivers the H2O2 to the catalyst regions where it gets decomposed and generated the O2 which in turn diffuses into the wound bed. The rate of H2O2 delivery was controlled by a pump. The rate of O2 generation can also be adjusted by changing the catalyst or H2O2 concentration in the solution. The choice of PDMS was advantageous here due to its gas permeability which allows the O2 to be diffused readily.

For sensing the oxygen concentration a phosphorescent oxygen-sensitive material was employed. Oxygen can quench the material and change the phosphorescence duration. The oxygen concentration is proportional to the decay rate of the phosphorescence signal and thus can be precisely measured. By combining these two materials (decomposing catalyst and sensing chemical) on the parchment and combining it with the microfluidic network for the fluid delivery, the flexible multi-layer microfluidic platform was able to concurrently sense and generate oxygen.

Read the original article: Integrated sensing and delivery of oxygen for next-generation smart wound dressings

References:

1- Oxygen: Implications for wound healing

2- Wound healing essentials: Let there be oxygen

Pouriya Bayat

Pouriya is a microfluidic production engineer at uFluidix. He received his B.Sc. and M.A.Sc. both in Mechanical Engineering from Isfahan University of Technology and York University, respectively. During his master's studies, he had the chance to learn the foundations of microfluidic technology at ACUTE Lab where he focused on designing microfluidic platforms for cell washing and isolation. Upon graduation, he joined uFluidix to even further enjoy designing, manufacturing, and experimenting with microfluidic chips. In his free time, you might find him reading a psychology/philosophy/fantasy book while refilling his coffee every half an hour. Is there a must-read book in your mind, do not hesitate to hit him up with your to-read list.